-

Compound Fertilizer Production LineView All Products

Compound fertilizer production line is a complete equipment system that integrates raw material processing, mixing, granulation, drying, screening and other multiple links. The core is to process nutrient elements such as nitrogen, phosphorus, and potassium into compound fertilizers in scientific proportions. According to the production process, it can be divided into physical mixing method, chemical reaction method, and blending method (BB fertilizer line). The physical mixing method is suitable for medium and low-concentration products and has a low cost; the chemical reaction method can produce high-concentration and high-stability composite fertilizers; the blending method does not require granulation, and the formula is flexible. According to the granulation technology, there are rotary drum granulation wire (suitable for large-scale production and uniform granules), disk granulation wire (small area, suitable for small and medium-sized production capacity), and extruded granulation wire (low energy consumption, suitable for viscous materials). Its production process includes raw material pretreatment (pulverization, screening), mixing (automatic measurement, accuracy up to ±0.5%), granulation and molding (adding binder to form particles, mainly 2-4mm in particle size), drying and cooling (water content drops to 2%-5%, cooling to room temperature), screening and packaging (separating unqualified particles, automatic packaging).

+

-

Grinding EquipmentView All Products

Grinding equipment is a critical component of industrial production systems, enabling the fine processing of materials. Its core function is to process various solid materials, such as ores, cement raw materials, pulverized coal, and slag, through specialized grinding processes to a specific fineness that meets subsequent production and processing standards and application performance requirements. Whether in coarse grinding pretreatment or ultrafine grinding, its performance directly determines the efficiency of material processing, the quality stability of the final product, and the control of energy costs during the production process, making it a crucial factor influencing the overall profitability of industrial production.

This type of equipment has an extremely broad application scope, encompassing a wide range of key industrial sectors, including cement production in the building materials industry, ore processing in the metallurgical industry, raw material refinement in the chemical industry, mineral processing in the mining industry, and pulverized coal production in the power industry. In the production processes of various industries, grinding equipment plays a key role in basic material processing, providing raw materials with the required particle size for subsequent core production processes such as forming, reaction, smelting, and combustion. It is an indispensable equipment type that ensures the smooth operation of the industrial production chain and helps achieve efficient, stable, and energy-efficient operation in material processing.

+

-

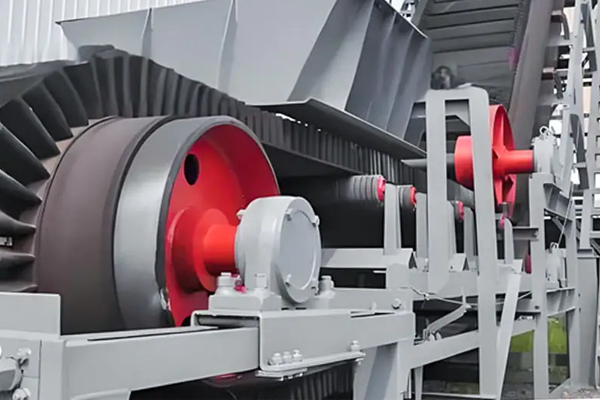

Material Feeding EquipmentView All Products

Material Feeding Equipment is an essential component of industrial production and material handling processes. It's primarily used to stably and evenly convey various bulk, granular, or powdered materials at a specific rate and pattern to subsequent processing, handling, or storage equipment. This type of equipment is widely used in industries such as mining, metallurgy, building materials, chemicals, grain processing, and the power industry. Depending on material characteristics (such as hardness, moisture, and particle size) and production requirements, it can be categorized into vibrating feeders, screw feeders, belt feeders, disc feeders, and electromagnetic vibrating feeders. For example, vibrating feeders use vibration to continuously move material along a trough, making them suitable for feeding bulk or granular materials. Screw feeders, on the other hand, propel material through the rotation of spiral blades, making them ideal for conveying powdered or small particles. They also offer closed-loop conveying, reducing dust pollution.

In terms of its purpose and function, the core function of material feeding equipment is to ensure continuous and controllable material transportation, thereby coordinating the production rhythm of upstream and downstream processes and improving overall production efficiency. On the one hand, it can precisely adjust the feed rate based on the processing capacity of downstream equipment, avoiding production interruptions caused by material accumulation or insufficient supply. For example, in a mineral processing line, a vibrating feeder can evenly feed the crusher to ensure stable crushing operations. On the other hand, some material feeding equipment also has the function of preliminary screening or mixing materials. For example, a vibrating feeder with a screen can remove large impurities during the feeding process, improving the purity of the material for subsequent processing. In addition, by combining automated control with material feeding equipment, remote control and intelligent speed regulation can be achieved, further adapting to the flexibility requirements of modern production lines and reducing the cost of manual intervention.

+

-

Dust Collection EquipmentView All Products

Dust collection equipment is a key device used in industrial production and environmental management to capture, separate, and collect dust particles. It utilizes various technologies, including filtration, centrifugal separation, and electrostatic adsorption, to effectively treat pollutants such as smoke and dust generated during production. Based on their operating principles and application scenarios, common dust collection equipment can be categorized as bag filters, electrostatic precipitators, cyclone dust collectors, and wet dust collectors. Bag filters, with their efficient bag filtration capabilities, are widely used in industries with high dust concentrations, such as metallurgy, cement, and chemicals. Electrostatic precipitators utilize an electrostatic field to absorb dust and are suitable for treating flue gas in high-temperature and high-humidity environments. Cyclone dust collectors rely on centrifugal force to separate dust and are often used for primary purification of larger dust particles. Wet dust collectors capture dust with a water mist and are particularly effective in flammable and explosive environments.

The core purpose of dust collection equipment is to control dust pollution, protect the health of operators, and reduce wear and tear on production equipment, thereby extending its service life. From an environmental perspective, it can effectively reduce dust emissions, helping companies meet national and local environmental emission standards and avoid fines and production halts caused by excessive emissions. Furthermore, some dust collection equipment can recycle and reuse dust. For example, in industries like grain processing and mineral processing, collected dust can be re-entered into production processes, improving resource utilization. Whether in large industrial plants or small processing workshops, choosing the right dust collection equipment is crucial for achieving clean production and green development.

+

-

Drying EquipmentView All Products

Drying equipment, a crucial material handling device in industrial production, is widely used in a variety of industries, including mining, environmental protection, and energy. Its core function is to remove excess moisture from materials through a rational heat source supply and efficient heat exchange, ensuring that the materials meet the required moisture content for subsequent processing, storage, or discharge. This provides critical support for the smooth operation of production processes and efficient resource utilization across various industries.

Drying equipment in this category is precisely categorized based on the characteristics, form, and processing requirements of the materials being processed in different industries. Each type of equipment undergoes targeted technical research and development and structural design to adapt to the drying process requirements of specific materials. Whether targeting specific granular, paste-like, or slurry-like materials, each type of drying equipment is designed to maximize the retention of the material's active ingredients while ensuring drying efficiency or meet the specific requirements of subsequent processing. This achieves specialized, efficient, and energy-saving drying of materials in various applications, providing powerful equipment support for enterprises to address excessive moisture content and improve production efficiency.

+

-

Conveying EquipmentView All Products

Conveying equipment refers to equipment that enables continuous or intermittent material transport through mechanical or pneumatic means, using devices such as conveyor belts, chains, pipes, and rollers. This type of equipment can handle a wide range of materials, including bulk materials such as coal, ore, and grain, as well as finished goods such as cartons, packages, and parts. It plays an indispensable role in various fields, including industrial production, logistics and warehousing, mining, and agricultural processing. Depending on the conveying method and structure, common conveying equipment includes belt conveyors, screw conveyors, chain conveyors, and pneumatic conveyors. Each of these conveying equipment utilizes unique designs to adapt to different working conditions.

In practical applications, the core function of conveying equipment is to improve material handling efficiency, reduce labor intensity, and ensure the stability and accuracy of the material transportation process. For example, in manufacturing production lines, conveying equipment can sequentially transport parts to various processing stations, ensuring smooth integration of automated production processes. In logistics warehouses, it can quickly sort, load, unload, and transfer goods, shortening cargo turnover times. In the mining and construction industries, large-scale conveying equipment can overcome terrain limitations and transport large quantities of bulk materials such as ore, sand, and gravel over long distances, reducing transportation costs. Furthermore, some specially designed conveying equipment features dustproof, explosion-proof, and corrosion-resistant features, meeting the stringent material handling requirements of industries such as food, pharmaceuticals, and chemicals.

+

-

Elevating EquipmentView All Products

Elevating Equipment is a critical piece of equipment responsible for vertical or steeply inclined material transport in industrial production. It is widely used in industries such as mining, building materials, chemicals, grain, coal, metallurgy, and power generation. It serves as a core link connecting upstream and downstream production processes and enabling efficient material transfer. It overcomes height limitations and operates continuously and stably, precisely transporting materials in various forms, such as granules, powders, and small lumps, from low locations to higher silos, production lines, or downstream processing equipment. This not only significantly improves production automation and overall efficiency, but also reduces the costs and safety risks associated with manual intervention, providing crucial support for the smooth operation of various industrial operations.

In terms of design and application adaptability, elevating equipment offers strong customization capabilities. It can be tailored to the physical properties of the material being transported (such as bulk density, abrasiveness, temperature, and humidity) and conveying requirements (such as lifting height, throughput, and operating environment). Different drive modes, hopper structures, and sealing designs can be employed to ensure reliable operation under various operating conditions. At the same time, its selection needs to be closely integrated with industry characteristics and specific production needs: for light transportation in small and medium-sized scenarios, there are models with compact structure and smooth operation to choose from; for medium and high abrasive materials or harsh working conditions, there are models that are wear-resistant and resistant to extreme environments; and for the large-scale and ultra-high-rise transportation needs of large enterprises, there are also heavy-duty models with high load capacity and large flow to meet them, fully covering the diversified material transfer needs of different industries.

+

-

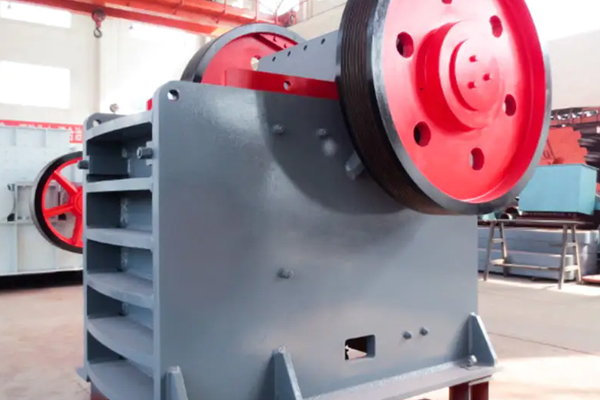

Crushing EquipmentView All Products

Crushing equipment is a key component in the mining, construction, and industrial processing industries, capable of crushing various materials into specific particle sizes. Based on the force applied, it can be categorized as either extrusion or impact crushers. Extrusion crushers, such as jaw, gyratory, cone, and roller crushers, crush materials by squeezing them between fixed and moving surfaces. They are suitable for hard materials like granite, producing less dust but more flake-like particles. Impact crushers, such as hammer and impact crushers, use high-speed rotating components to impact the material, causing high-frequency collision and shearing to pulverize the particles. They are commonly used for low- to medium-hardness materials, achieving high crushing ratios and fine particle shape.

Based on the operation stage, crushing equipment can be categorized as coarse, medium, fine, and sand-making and shaping equipment. Jaw or gyratory crushers are commonly used for coarse crushing, offering large feed openings and high processing capacity. Cone and impact crushers are used for medium and fine crushing. The former is suitable for hard rock, while the latter is used for low- to medium-hardness materials and produces fine particle shape. Vertical shaft impact crushers are often used for sand-making and shaping, offering high efficiency and controllable gradation. These equipments are matched with feeding, screening and conveying equipment to form a complete production line to meet the material processing needs of different industries.

+

-

Screening EquipmentView All Products

Screening equipment is specialized equipment that uses particle size differences to grade and sort materials through a screen or other separation device. It is widely used in a variety of fields, including mining, building materials, metallurgy, chemicals, food, and environmental protection. This type of equipment typically uses forces such as vibration, rotation, and airflow to move materials through the sieve apertures, achieving separation. Based on their structure and operating principle, they can be categorized into various types, including vibrating screens, fixed screens, drum screens, airflow screens, and probability screens. Different types of screening equipment adapt to varying material characteristics (such as particle size, moisture content, and viscosity) and production requirements. They can handle both coarse, bulk materials and fine powders, making them key equipment for refined sorting in material handling processes.

In industrial production, the core role of screening equipment is to improve material purity and optimize production efficiency. For example, in mining, it separates ore from waste rock, providing qualified raw materials for subsequent crushing and beneficiation processes. In the construction industry, it can grade sand and gravel to ensure that the gradation of concrete aggregates meets standards. In food processing, it can filter out impurities and unqualified particles to ensure product quality. In addition, screening equipment can also achieve resource recycling, such as screening and recycling industrial waste to reduce waste emissions. At the same time, precise classification can reduce energy consumption in subsequent processes, providing a stable material base for large-scale production.

+

-

Industrial Mixing and Agitation EquipmentView All Products

In the industrial sector, industrial mixing and agitation equipment is a core component that ensures efficient production processes. Its design and performance directly impact the quality, stability, and production efficiency of industrial products. To address the high viscosity, hardness, and corrosive properties of industrial materials, this equipment utilizes high-strength materials (such as stainless steel and titanium alloys) and precision transmission mechanisms to handle a wide range of industrial material mixing needs, from powders and granules to high-viscosity slurries.

From a practical perspective, industrial mixing and agitation equipment is a key enabler for industrial process upgrades. In heavy industries such as metallurgy and mining, it is used to stir ore slurries and mix reagents, improving mineral flotation efficiency. In the energy industry, mixing biomass fuels and mixing asphalt rely on specialized equipment to ensure uniform composition, enhancing combustion efficiency or workability. In the production of new materials, the dispersion of nanomaterials and the mixing of composite materials require high-precision mixing equipment to ensure uniform microstructure. In addition, industrial-grade industrial mixing and agitation equipment can effectively solve problems such as material sticking to the wall and mixing dead corners in industrial production by optimizing the shape of the mixing blades (such as anchor type, frame type, and propeller type), reducing material loss. At the same time, it can adapt to extreme industrial environments such as high pressure and high temperature, providing reliable protection for safe production in high-risk industries such as chemical and petrochemical industries. It is an important equipment for achieving cost reduction and efficiency improvement in industrial modernization production.

+

-

Granulation EquipmentView All Products

Granulation equipment is a key component of material granulation in industrial production. It transforms dispersed raw materials into granules of a specific size and strength through physical or chemical reactions. This not only facilitates material storage, transportation, and metering, but also improves subsequent processing efficiency and product quality. It is widely used in fertilizers, metallurgy, building materials, and other fields. For example, granulating fertilizer raw materials reduces nutrient loss and improves fertilization uniformity. In mineral processing, granulation optimizes the material's smelting properties. Its core function is to precisely control the granulation process to meet the specific material form requirements of various industries, making it a crucial link between raw material processing and finished product production.

Among granulation equipment types, drum granulators and pan granulators are two common types. Drum granulators utilize an inclined, rotating drum to continuously tumble the material within the drum due to gravity and friction. Combined with a sprayed binder, the drum granulator achieves agglomeration and granulation. It is suitable for large-scale production and is particularly effective in the production of compound fertilizers, organic fertilizers, and other fertilizers. It features high throughput and high granule strength. The disc granulator rotates an inclined disc and uses the synergistic effect of centrifugal force, gravity and friction to form particles at the edge of the disc, making it easy to observe the granulation process. The particles have good sphericity and are often used in laboratory tests or small and medium-sized production. They are more common in particle preparation in the fields of ceramics, catalysts, etc.

+

-

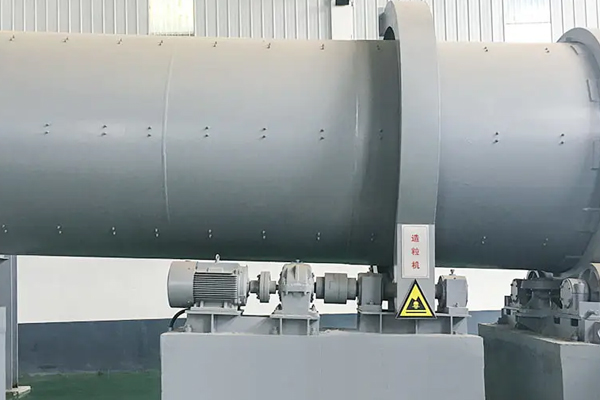

Calcination EquipmentView All Products

Calcination equipment is a type of industrial equipment used for high-temperature material processing. It uses direct or indirect heat sources to provide the required high-temperature environment for the material, promoting physical or chemical changes. Common types include rotary kilns and calciners. Rotary kilns are typically cylindrical and rotate slowly at a certain angle, allowing the material to tumble and move within them, ensuring even heating. Calcination furnaces can employ a variety of heating methods to meet the temperature and atmosphere requirements of different processes.

In the metallurgical industry, calcination equipment is used to roast ores, such as oxidative roasting of chromium and ferronickel ores, to improve their smelting properties. In the chemical industry, it can be used to treat catalyst materials to enhance their activity and stability. In building materials production, cement rotary kilns calcine raw materials into cement clinker, while lime rotary kilns are used to produce quicklime. Calcination equipment also plays an indispensable role in processing specialty materials, recovering rare metals, and treating solid and hazardous waste in the environmental protection sector, helping various industries achieve efficient and high-quality production goals.

+

Building Materials Machinery encompasses a range of industrial equipment designed for the processing and production of construction and infrastructure materials. The core function of this machinery is to transform raw materials—such as ores, aggregates, and industrial by-products—into finished or semi-finished building materials through processes including crushing, mixing, heat treatment, granulation, and coating. Key performance metrics for this equipment include processing capacity, energy efficiency, operational stability, and automation level. The product lines often feature robust construction for heavy-duty applications, integrated control systems for precise process management, and designs focused on reducing environmental impact through dust collection and heat recovery. As a specialized manufacturer, Nantong Alisen Environmental Protection Technology Co., Ltd. provides a comprehensive portfolio of Building Materials Machinery, including rotary kilns for calcination, drum granulators for material forming, and dryers/coolers for thermal processing, which are integral to establishing efficient and modern production lines.

Comparison & Selection Guide

Different types of Building Materials Machinery serve distinct functions within a production line. Understanding their roles is crucial for selecting the correct equipment.

-

Rotary Kiln vs. Dryer:

-

Rotary Kiln: Primarily used for high-temperature calcination processes, causing chemical or physical changes in the material. It is essential for producing cement clinker, lime, and certain refractory materials.

-

Dryer: Designed to remove moisture from materials through heat exchange. It is applied in drying sand, slag, or clay without necessarily inducing a chemical change.

-

-

Granulator vs. Coater:

-

Granulator (e.g., Drum Granulator): Its function is to form fine powders into larger, solid granules to improve flowability, reduce dust, and enhance application properties.

-

Coating Machine: Applied after granulation, it adds a protective coating layer to the granules to prevent caking, reduce dust, and control nutrient release rates.

-

How to Choose:

The selection of appropriate Building Materials Machinery depends on the raw material properties, desired final product specifications, required production capacity, and site-specific energy and space constraints. Nantong Alisen offers technical consulting to help clients configure the optimal machinery combination for their specific project needs.

Frequently Asked Questions (FAQ)

Q1: Why does building material production require so many types of machinery?

Different raw materials have significantly different physical properties. For example, cement powder, sand, and chemical powders require different processing methods. Therefore, the production line needs machinery in multiple stages to complete different processes.

Q2: What are the most important processing steps for powder-based building materials?

Usually, it's "uniform mixing" and "moisture control," which are crucial for the stability of the molding process.

Q3: Why are dryers and coolers used together?

Dried materials are at high temperatures and need cooling to ensure storage stability and prevent agglomeration.

Q4: Why is the design of conveyor equipment important?

Conveying speed affects the overall production line rhythm, and the structural design determines whether the production line can operate continuously.

Q5: Do different materials require different types of equipment?

Yes, differences in material viscosity, density, particle size, and moisture content lead to different choices in equipment structure and parameters.

The Role of the Rotary Kiln in Modern Industry

The rotary kiln is a cornerstone of modern building materials production. It is a large, rotating cylindrical furnace that is slightly inclined. Materials are fed into the upper end, and as the kiln rotates, they gradually move down toward the flame at the lower end. During this journey, they are subjected to temperatures high enough to trigger calcination or sintering—processes that fundamentally alter the material's chemical composition to create strong, stable products like cement clinker. This continuous thermal processing is vital for achieving the uniform quality required in large-scale construction projects.

What is a Complete Production Line?

A complete production line is a synchronized set of machines where the output of one machine becomes the input for the next. For example, in a simple aggregate processing line, a crusher breaks down large rocks, a conveyor transports the crushed material to a screen for sizing, and finally, different sized materials are directed to storage. The expertise of a company like Nantong Alisen lies not only in manufacturing each machine but, more importantly, in engineering them to work together efficiently as a unified system, thereby maximizing overall productivity and minimizing operational costs.

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español