The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MORESlag Dryer

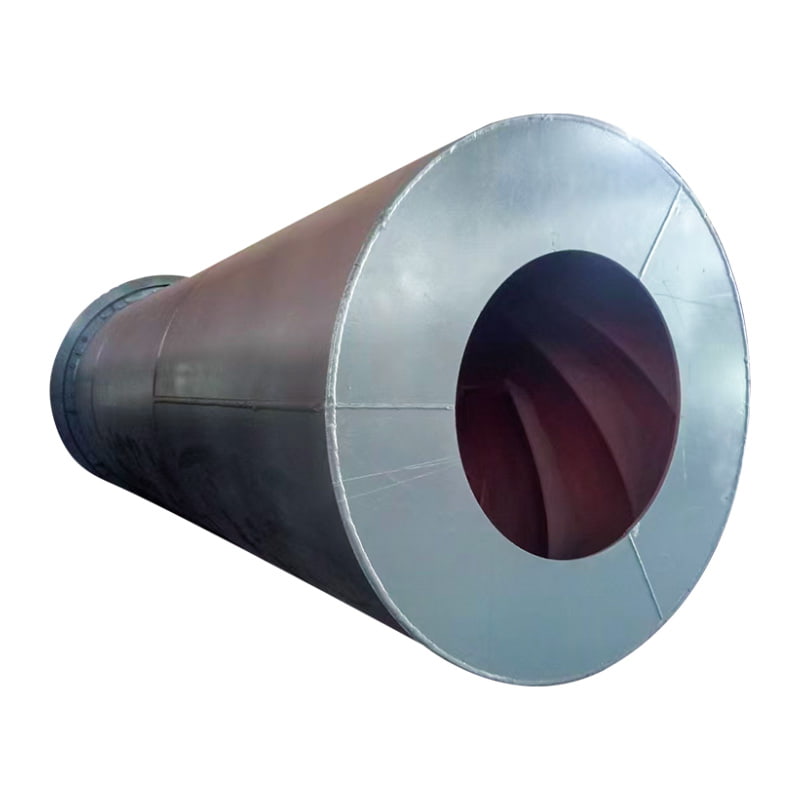

The slag dryer features a rational design and fine workmanship, stable performance, advanced technology, high output, low energy consumption, a compact footprint, and a high degree of mechanization.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Suitable for drying slag, carbide slag, limestone, clay, river sand, quartz sand, slag, and other materials.

Product Introduction

The slag dryer is a rotary dryer primarily composed of a rotating drum, induced draft equipment, high-speed disintegration equipment, a lifting plate, a self-cleaning device, a transmission, a conveying system, a hot air system, a speed reducer, a support system, and a sealing device. The slag dryer features a rational design and fine workmanship, stable performance, advanced technology, high output, low energy consumption, a compact footprint, and a high degree of mechanization.

Key Advantages

● Optimized structural design of key components makes the entire equipment more cost-effective

● Utilization of high-performance materials and processing techniques ensures smooth operation and reliable use

● Easy maintenance and significantly reduces repair workload

● A variety of equipment options are available to meet the needs of different production processesOperating Principle

The rotary dryer drum is arranged at a certain inclination relative to the horizontal. Material enters the drum through the feed inlet and is lifted by the centrifugal force generated by the drum's rotation and the action of internal mechanisms. It then undergoes sufficient heat exchange with the hot air, continuously raising the material temperature and evaporating moisture. Material that meets the moisture requirement is discharged from the discharge device, and the air carrying the water vapor is extracted, completing the drying process. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español