The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MORESludge Dryer

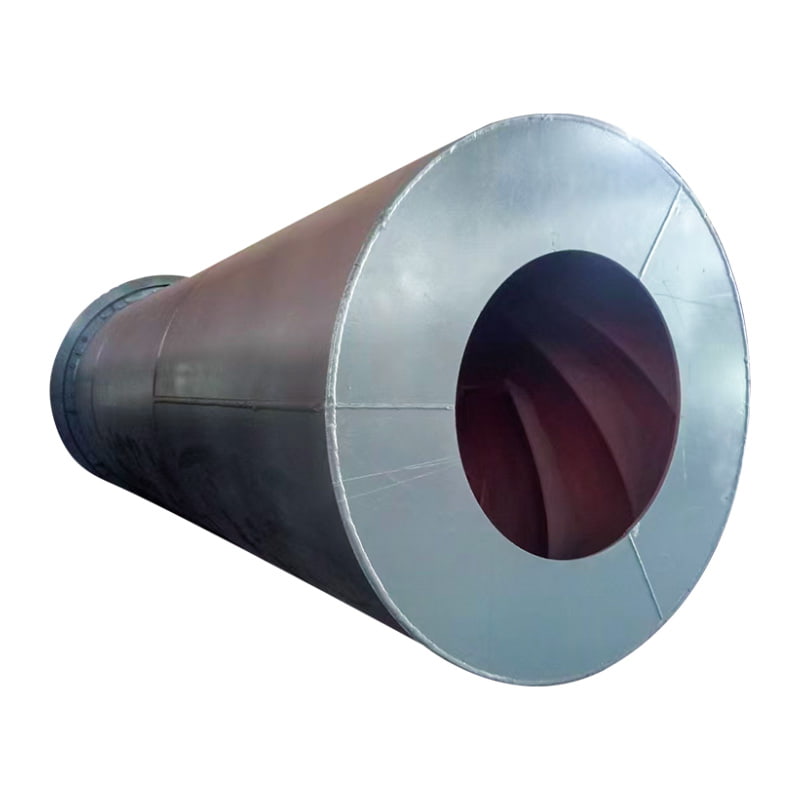

Our sludge dryer products are available in 14 different sizes, ranging from Ø1.2×12m to Ø4.2×42m. Drum speeds range from 2.09-5r/min, and main motor power ranges from 11-400kW. They can dry 2-46 tons of material per hour.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Various sludges and high-viscosity materials.

Product Introduction

To address the tendency of sludge to agglomerate during dewatering, we have modified the feed plate structure of conventional single-channel dryers and adopted a combined self-cleaning device. This significantly expands the application range of single-channel dryers, making them suitable for drying not only various types of sludge but also various high-viscosity materials.Key Advantages

● Can process sludge with a moisture content of 90% and boasts strong adaptability.

● Equipped with a lifting plate within the drying drum, the material is evenly heated and thoroughly dried.

● The dryer boasts a high degree of automation, utilizing an advanced fuzzy control system for automatic control of product quality.

● The sludge dryer boasts a rational structure, superior workmanship, high output, low energy consumption, and easy operation.Operating Principle

Sludge is fed from a feeder through a chute onto the guide plates within the sludge dryer. As the drum rotates, the sludge is directed onto the inclined lifting plates, where it is lifted to the center of the drum and gradually dispersed, forming a material curtain. High-temperature air flows through this curtain, preheating the sludge and evaporating some of its moisture. As the sludge falls and moves onto the movable grate wings, it mixes with the preheated grate wings, transferring heat to the material and evaporating some of its moisture. Simultaneously, the wings carry the material, lifting and dispersing it repeatedly, creating a continuous flow of heat through convection and contact with the hot air. Simultaneously, a cleaning device embedded in the material slides down the inside of the arc-shaped lifting plate, clearing any material adhering to the inner wall. After the cleaning device rotates with the cylinder past the vertical line, it drags along the back of the arc-shaped lifting plate, clearing any material adhering to the outer wall. The continuous rotation of the sludge dryer cylinder evaporates some of the moisture, further drying the sludge. The cleaning device also breaks up sludge clumps, accelerating drying speed. After drying, the sludge becomes a low-moisture, loose material that is discharged from the sludge dryer's outlet. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español