The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MORECoal Slime Dryer

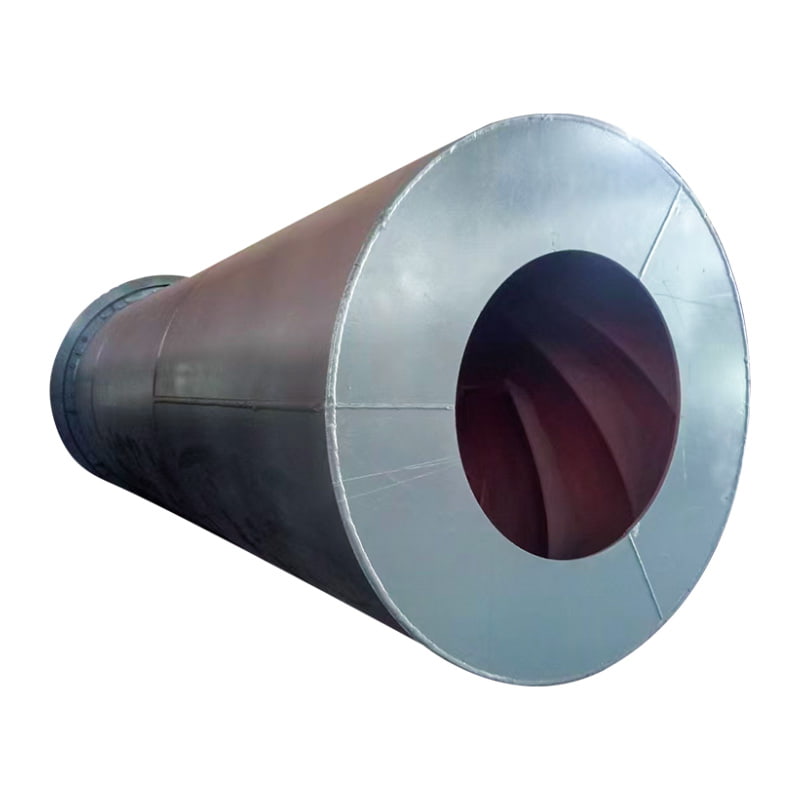

Our coal slime dryers are available in 14 different sizes, ranging from Ø1.2×12m to Ø4.2×42m. Drum speeds range from 2.09 to 5 rpm, and main motor power ranges from 11 to 400 kW. They can dry 2 to 46 tons of material per hour.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Drying sticky filter cake materials such as coal slime, washed clean coal, municipal sludge, coal slime, choline chloride, red mud, and bio-waste residue.

Product Introduction

The coal slime dryer is a new type of specialized coal slime drying equipment developed by our company based on existing dryers. Equipped with a deagglomeration mechanism, movable grate wings, a cleaning device, and a crushing and impacting device, it can dry sticky materials that conventional rotary dryers cannot handle. Designed specifically for sticky filter cake-like materials, it is suitable for drying these materials.

Key Advantages

● The coal slime dryer has a large processing capacity and is suitable for large-scale production with a single-unit production capacity of 1 to 40 tons/hour.

● The coal slime dryer has low operating costs and a high volumetric heat transfer coefficient of 300-450 kcal/m³·°C·h.

● The drum speed can be adjusted steplessly. By adjusting the drum speed and the dryer's inlet air temperature, it can adapt to different feed material properties and meet different product moisture requirements.

● The equipment operates reliably and has strong overload resistance. The self-aligning roller structure reduces wear and power consumption. A specialized retaining wheel structure reduces horizontal thrust caused by tilting the equipment.Operating Principle

The coal slime is delivered to the hopper by a belt conveyor or bucket elevator. Then, it enters the feed end through the hopper feeder and a feeding pipe. The feeding pipe's slope should be greater than the natural inclination of the material to ensure smooth material flow into the coal slime dryer. The coal slime dryer cylinder is a rotating cylinder slightly inclined to the horizontal. Material is fed from the higher end, while a heat carrier enters from the lower end, contacting the material in countercurrent flow. Sometimes, the heat carrier and material enter the cylinder together. As the cylinder rotates, the material is drawn to the lower end by gravity. As the wet material moves forward within the cylinder, it is directly or indirectly heated by the heat carrier, drying it. It is then discharged at the discharge end via a belt conveyor or screw conveyor. A scooping plate is installed on the inner wall of the coal slime dryer cylinder. Its function is to scoop up and drop the material, increasing the contact surface between the material and the airflow, thereby increasing the drying rate and promoting material forward movement. The heat carrier is generally hot air or flue gas. After passing through the dryer, a cyclone dust collector is generally required to capture the material entrained in the air. To further reduce the dust content of the exhaust gas, it should also pass through a bag filter or wet dust collector before discharge. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español