Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORESpray Granulation Dryer

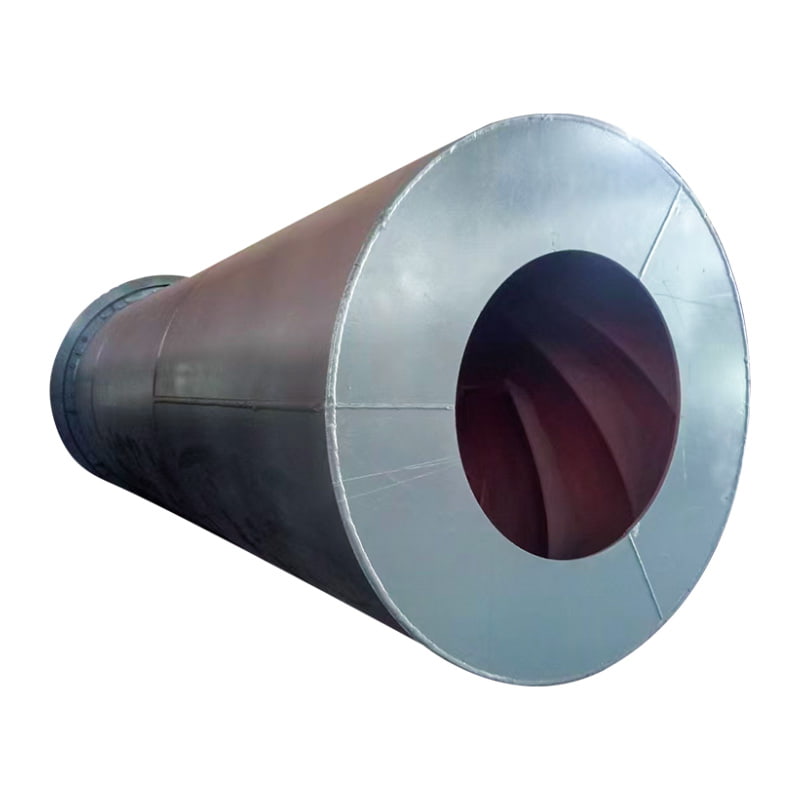

The spray granulation dryer combines traditional spraying, granulation, and drying processes within a single rotary device, utilizing new technologies such as high-strength bricks, heat transfer, and internal classification, internal material return, and internal crushing.

-

SPECIFICATIONS

-

CONTACT US

-

Structural Principle:

The spray granulation dryer operates by pumping a high-pressure pump into a specially designed atomizing nozzle, where it is atomized into fine droplets. These droplets then contact the fine particle nuclei within the rotating cylinder, adhering to the surface of the nuclei. Under the action of the high-temperature drying medium, heat and mass exchange rapidly completes, causing the particles to grow. The enlarged particles are then screened, and the finer particles are returned as nuclei. Some of the powdered material is also returned as nuclei.

Technical Advantages:

1. High production capacity, strong operational flexibility, energy savings, and a shortened process flow.

2. Drying and granulation of solutions and high-temperature molten liquids are completed in one operation.

3. Stable operation, simple operation, and long service life.

4. Low operating costs and high thermal efficiency.

5. High product quality and high material yield. 6. The spray granulation dryer has a large output per unit -

Message Feedback

-

-

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE -

The agricultural industry relies heavily on efficient and reliable fertilizer manufacturing systems to meet the growing global food demand. Among these, the Compound Fertilizer Pro...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español