The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

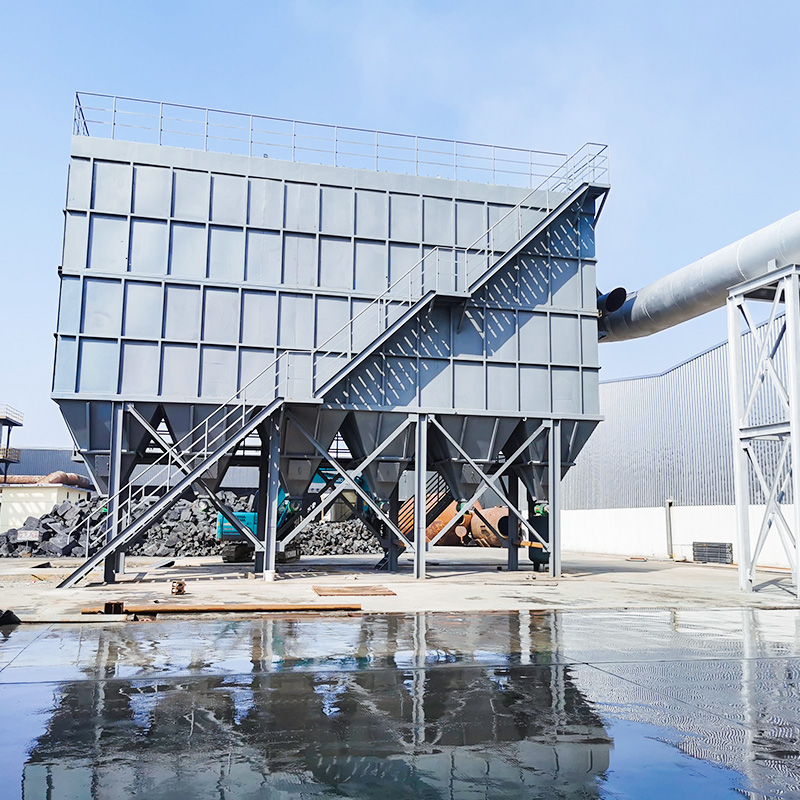

READ MOREBoiler Pulse Dust Collector

A boiler pulse dust collector removes particulate dust from flue gas emitted by fuel combustion in boilers, thereby reducing the flue gas concentration in the atmosphere. This is a crucial device for improving environmental pollution and air quality.

-

SPECIFICATIONS

-

CONTACT US

-

Classifications of Boiler Pulse Dust Collectors

Based on their operating principle, boiler pulse dust collectors can be categorized as steam dust collectors, bag dust collectors, boiler desulfurization dust collectors, and vertical kiln bag dust collectors.

Features of Boiler Pulse Dust Collectors

1. Boiler pulse dust collectors are dust removal devices used on boilers. To prevent dust containing sparks from directly entering the dust collector and damaging the filter bags, and to extend the dust collector's service life, a spark arrestor is installed before the dust collector's air inlet. This shatters and extinguishes small sparks trapped in the dust before it enters the dust collector for filtration.

2. The boiler pulse dust collector utilizes a powder spraying device and a bypass device, effectively preventing dust from sticking to the filter bags and reducing the temperature entering the baghouse, significantly extending the bag's service life.

3. The boiler pulse dust collector's air inlet duct and dust collector housing are insulated, and the outer wall panels of the dust hopper are heated and then insulated with electric heating plates.

Protective Measures for Boiler Pulse Dust Collectors

1. The air inlet duct, body, and ash hopper of the boiler pulse dust collector require insulation to prevent condensation.

2. Temperature detection and automatic alarm devices are installed at the air inlet and exhaust ports of the boiler pulse dust collector, and a cold air inlet device is installed at the air inlet. If the flue gas exceeds the operating temperature range of the baghouse, an alarm is triggered and temperature control measures are automatically implemented to ensure the dust collector operates properly.

3. The ash hopper is equipped with an electric heating and vibration device to prevent condensation caused by excessive condensation. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español