The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

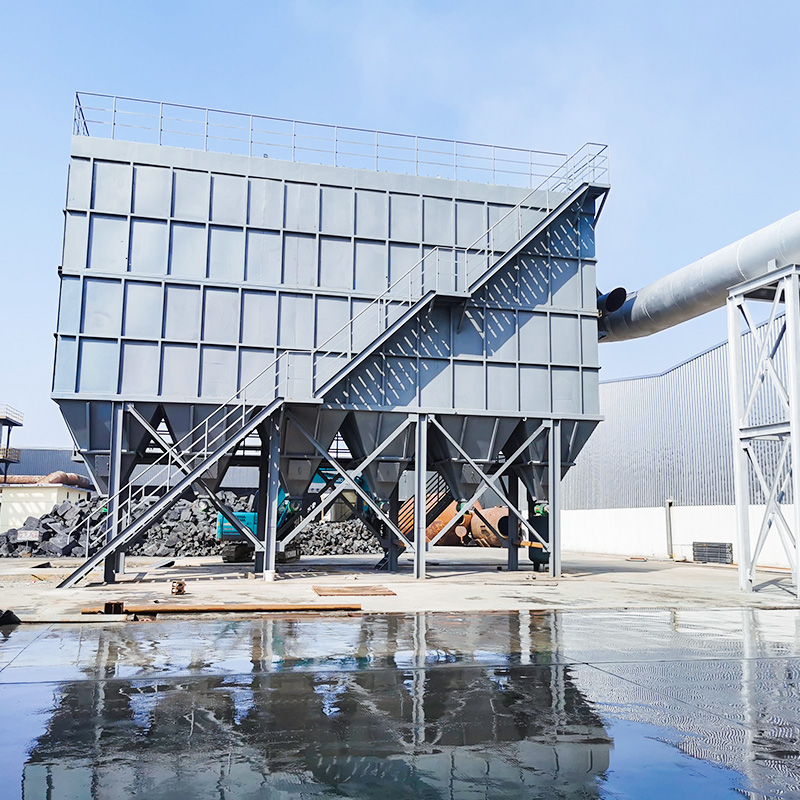

READ MOREPulse-Jet Dust Collector

TDMC's chambered pulse-jet bag dust collector is a new, highly efficient, low-pressure, long-pulse bag dust collector. It combines the advantages of chambered backflush and pulse-jet cleaning, while featuring longer filter bags to maximize the powerful cleaning effect of compressed air. This overcomes the shortcomings of chambered backflush and the simultaneous operation of pulse cleaning and dust filtration, preventing dust re-adsorption and loss of control. This improves filtration speed, saves cleaning energy, and extends filter bag life.

-

SPECIFICATIONS

-

CONTACT US

-

Operating Principle

The dust collector consists of a hopper, upper chamber, middle chamber, and lower chamber. The upper, middle, and lower chambers are chambered. During operation, dust-laden air enters the hopper through the air inlet duct. Coarse dust falls directly into the bottom of the hopper, while fine dust is carried upward by the airflow into the middle and lower chambers.

Dust accumulates on the outer surface of the filter bags. Filtered air enters the upper chamber and travels to the clean air manifold—the exhaust duct—before being discharged to the atmosphere by an exhaust fan. The dust in the hopper is discharged by a conveying system.

The cleaning process begins by shutting off the clean air outlet duct of the chamber, eliminating airflow through the bag filters. The pulse valve is then opened, and compressed air is directed from the air source through the air bag, pulse valve, and nozzle on the injection pipe in a very short time (0.065-0.085 seconds) to clean each filter bag. The shut-off valve is closed for a sufficient time to ensure that dust removed from the filter bags after the injection process settles into the hopper, preventing dust from being "re-adsorbed" by the air flow onto adjacent filter bags after leaving the bag surface. This ensures thorough bag cleaning. A PLC programmable controller automatically controls the exhaust valve, pulse valve, and ash discharge valve.

Main Features

1. Utilizing separate chamber airflow-stop pulse injection cleaning technology, this system overcomes the shortcomings of pulse dust collectors and separate chamber backflush systems. It offers strong cleaning capacity, excellent dust removal results, low emission concentrations, minimal air leakage, low energy consumption, minimal footprint, reliable operation, and excellent economic benefits.2. By utilizing pulse jet cleaning in separate chambers with airflow shutoff, thorough cleaning is achieved with a single jet. This extends the cleaning cycle, reduces cleaning energy consumption, and significantly reduces compressed air consumption. This also reduces fatigue on the filter bags and pulse valves, exponentially increasing their lifespan.

3. Inspection and bag replacement can be performed in separate chambers without stopping the system fan and under normal system operation. The filter bags utilize elastic expansion rings for excellent sealing and reliability. The polygonal filter bag cage reduces friction between the bag and cage, extending bag life and facilitating bag removal.

4. The bag system utilizes an upper extraction system. During bag replacement, the cage is withdrawn and the dirty bags are placed in the lower hopper of the chamber and removed through a manhole, improving bag replacement operating conditions.

5. The chamber features an airtight design for excellent sealing. The inspection door is made of high-quality sealing material. Kerosene is used for leak detection during the manufacturing process, resulting in a very low air leakage rate. 6. Equipped with the Bi-Get energy-saving system and the Emc bag cleaning system, the system operates with low energy consumption.

7. The inlet and outlet ducts of the chambered pulse jet bag dust collector are compactly arranged, reducing airflow resistance.

8. The entire system is controlled by a PLC, enabling automatic dust cleaning and unloading, automatic temperature control, and an over-temperature alarm.

-

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español