The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

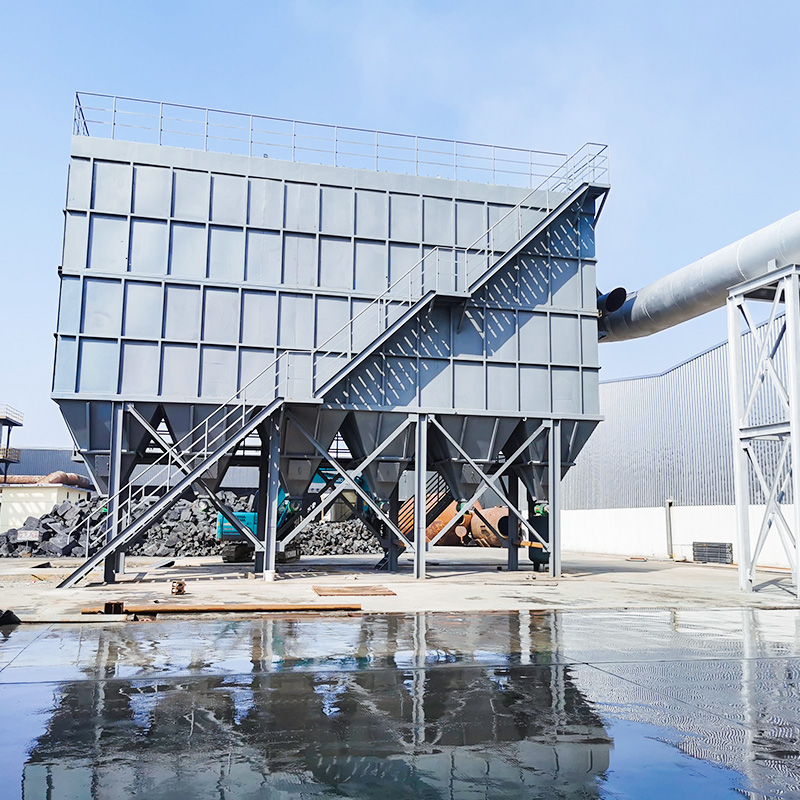

READ MOREHigh Temperature Pulse Jet Bag Dust Collector

The GMC pulse bag dust collector is a new type of dust collector developed by our company by introducing, digesting, and absorbing foreign technologies while incorporating Chinese characteristics. This pulse bag dust collector utilizes high-pressure (0.5-0.4 MPa) high-flow pulse valves to jet dust through each filter bag individually. It can collect over 99.9% of fine dust (particles ≤ 5 μm, content ≥ 70%) from gases containing large amounts of fine dust. It operates stably in exhaust gas dust removal from kilns, dryers, coolers, and other applications, with emission concentrations below 100 mg/Nm³. This type of dust collector is leading the domestic market. Under current environmental protection requirements, it is widely used not only in cement plant dust control but also in the deep processing of non-metallic mineral micropowders. It also has promising application prospects in the power, chemical, metallurgical, and steel industries.

-

SPECIFICATIONS

-

CONTACT US

-

Structure and working principle

1. Pulse bag dust collector structure The equipment mainly consists of the following parts:

(1) Box: including bag chamber, pre-dust collection chamber, clean air chamber, porous plate, dust bag, filter bag frame. The box is designed to withstand a pressure of 9000Pa.

(2) Injection system: main air pipe, injection pipe, pulse valve, controller.

(3) There are two types of ash hopper and ash discharge part: one is that the ash hopper is directly connected to the ash discharge valve, and the other is that the ash hopper is connected to the ash discharge valve through a conveying device (such as a screw conveyor). The pulse bag dust collector body is designed with a full-steel structure, and the plate is cold-stamped to increase strength and improve equipment quality. This pulse bag filter not only handles ambient temperature gases, but its structure is also suitable for handling high-temperature gases. If insulation is required, the outer shell can be insulated with a double layer of LBY lightweight rock wool board. The outer shell is protected with 0.5mm thick galvanized sheet metal and installed using a new pull-out rivet process. Different filter media and filtration air velocity are selected based on the operating environment.

2. Working Principle

Dust-laden gas enters the enlarged hopper of the dust collector for pre-collection. It is then distributed between the filter bags via guide plates, where dust is retained on the outer surfaces of the bags. To minimize the equipment resistance (>1200Pa), high-pressure gas is pulsed through a solenoid valve. Compressed air (0.5-0.7MPa) is ejected from the perforations of the blowpipe (called the primary air) through a venturi. This induction channel induces ambient air (called the secondary air) several times the primary air volume into the dust bag, where it expands rapidly and, along with the reverse airflow, shakes off dust, achieving the desired cleaning effect. Using a microcomputer automatic control device, the cleaning cycle and pulse spray time are adjusted according to the dust, so that the dust collector can operate within the specified range.3. Selection parameters and selection principles

(1) The main technical parameters for selecting a pulse bag dust collector are air volume, gas temperature, dust concentration and humidity. According to the process design air volume, gas temperature, dust concentration, the maximum value is slightly smaller than the value in the technical performance table. The corresponding pulse bag dust collector model is the required pulse dust collector model. The dust filter bag used is determined according to the inlet concentration, gas temperature and humidity content.

(2) The gas consumption in the table is the case of centralized air supply in Plant I. If an air machine is used alone, the actual gas consumption should be increased to 1.5 times the value in the table.

(3) In the compressed air consumption column, the consumption mentioned is the gas consumption of the equipment of this model.

-

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español