The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

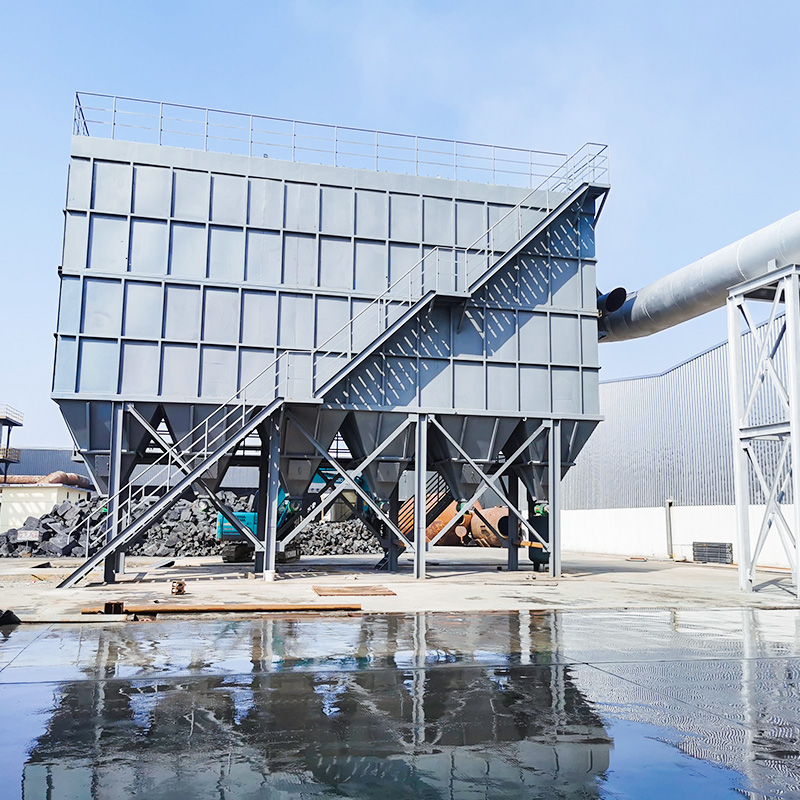

READ MOREDMC Series Single-Unit Pulse Dust Collector

Our DMC series single-unit pulse dust collectors are available in nine models, depending on the number of filter bags. They handle air volumes from 700 m³/h to 21,600 m³/h, with outlet gas concentrations below 30 mg/m³, meeting environmental emission standards. They feature low dust collector resistance and high efficiency.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Widely used for dust removal and purification of non-fibrous industrial dust and material recovery in industries such as metallurgy, building materials, machinery, chemicals, and mining.

Product IntroductionOur DMC series single-unit pulse dust collectors are small bag-type dust collectors optimized and improved by integrating similar products from both domestic and international sources. They utilize a pulse jet cleaning method, offering excellent cleaning performance, high purification efficiency, large air volume, long filter bag life, minimal maintenance, and safe and reliable operation.

Key Advantages

● Small footprint, low noise, compact design, and low investment

● Injection is achieved by directly activating the solenoid valve with an electronic signal, resulting in high instantaneous air volume and excellent airflow.

● Polyester needle-punched felt filter bags provide high dust removal efficiency, long bag life, and low emission concentrations.

● The housing is welded from bent sheet metal, ensuring high rigidity and reliability while maintaining a sleek and aesthetically pleasing appearance.

● Operating Principle

During operation, dust-laden air enters the filter chamber through the hopper (or lower open flange). Coarser particles fall directly into the hopper (or silo). The dust-laden air is filtered by the filter bags, with dust trapped on the outer surface. Clean air flows through the bag openings to the clean air chamber and is discharged into the atmosphere by the fan. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español