The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

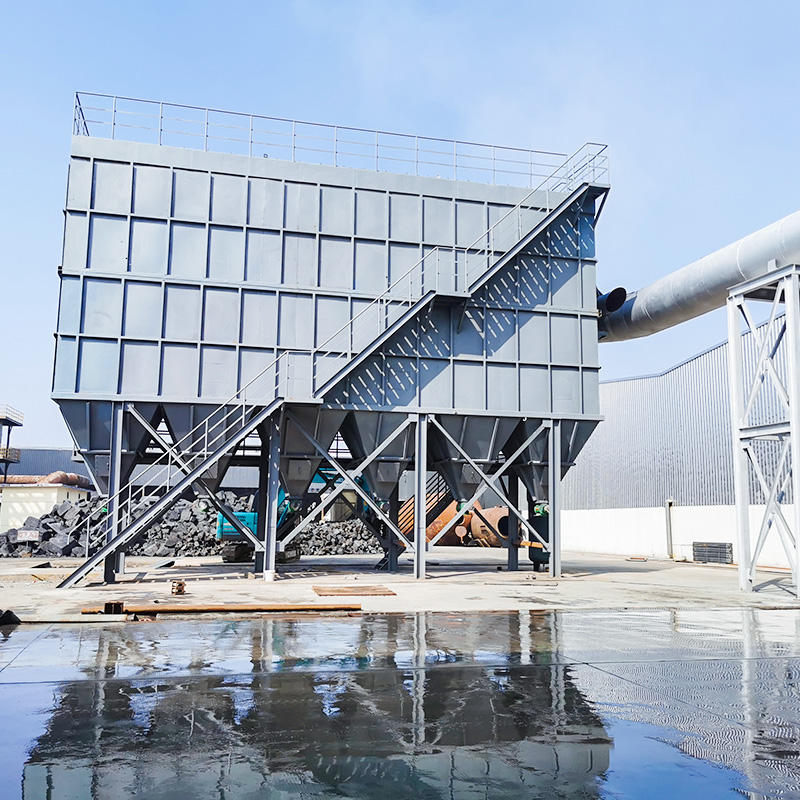

READ MOREAir Box Pulse Bag Dust Collector

The PPC series air box pulse bag dust collector is suitable for controlling high-concentration dust, simplifying dust control processes and reducing equipment investment. It is widely used in the building materials, cement, metallurgy, machinery, chemical, and refractory industries. It is particularly suitable for dust collection systems (or dust removal systems) in cement plants, such as crushing, packaging, silo roofs, clinker coolers, and various grinding mills. It can also be used for coal mill dust collection, but requires additional explosion-proof measures and structural modifications.

-

SPECIFICATIONS

-

CONTACT US

-

Application Areas

Applicable to the building materials, metallurgy, machinery, and chemical industries.

Product Introduction

The PPC series air box pulse bag dust collector combines the advantages of various bag dust collectors, including chambered backflush and pulse jet cleaning, while overcoming the shortcomings of chambered backflush and the need for simultaneous pulse jet and filtration. This expands its application range. This product features integrated chamber cleaning and utilizes large-scale pulse valves for cleaning, resulting in strong cleaning capacity, excellent results, and a long service life. This product is suitable for controlling high-concentration dust, simplifying dust control processes and reducing equipment investment. It is widely used in the building materials, cement, metallurgy, machinery, chemical, and refractory industries. It is particularly well-suited for dust collection systems (or dust removal systems) in cement plants, such as crushing, packaging, silo roofs, clinker coolers, and various grinding mills. It can also be used for coal mill dust collection, but requires additional explosion-proof measures and structural modifications. Dust-laden gas enters the dust collector through the air inlet, is diverted by an inclined baffle, and enters the ash hopper (the PPC32 model enters from the ash hopper). Simultaneously, the airflow slows down, and due to inertia, coarse dust particles in the gas fall into the ash hopper, while fine dust particles are carried upward by the airflow into the filter chamber. The dust adheres to the outer surface of the filter bags. The purified gas passes through the filter bags and enters the upper clean room. From the various sub-cleaning rooms, it is collected and drawn out through the air outlet by the dust collection system's main fan and discharged into the atmosphere.

Highlights:

● The PPC series air box pulse bag dust collector features integrated cleaning in separate chambers.

● Utilizes large-scale pulse valves for cleaning, providing strong cleaning capabilities.

● Excellent dust removal performance and long service life.

● This product is suitable for the control of high-concentration dust and can simplify dust control processes. Reduce Equipment Investment.Working Principle

Under the influence of the induced draft fan, dust-laden air enters the dust collector through the air inlet and is diverted by the inclined baffle to the ash hopper. As the airflow slows, coarse dust particles in the air fall into the ash hopper due to inertia and gravity. Fine dust particles are carried upward by the airflow into the filter chamber. After being filtered and purified by the filter bags, the dust adheres to the outer surface of the filter bags. The purified air enters the upper clean chamber. Clean air from each sub-chamber is collected in the clean chamber and sucked out by the induced draft fan and discharged into the atmosphere. The cleaning process first shuts off the clean air outlet duct of the chamber, eliminating airflow through the bag (sub-chamber air is shut off for cleaning). Then, the pulse valve is opened to use compressed air for pulsed cleaning. The exhaust valve, pulse valve, and ash discharge valve are fully automatically controlled by a programmable controller. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español