The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MORENE Bucket Elevator

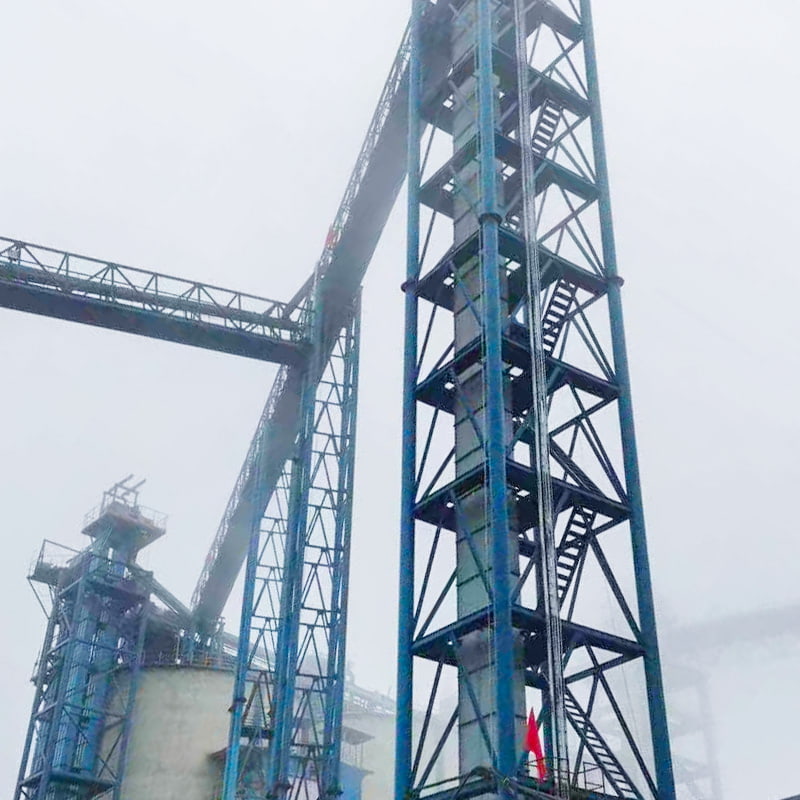

Our NE-type plate chain bucket elevators, NE15-NE400, are available in eight sizes. The ribbed housing provides strong rigidity, high precision, easy operation and maintenance, and a compact design. They can convey 16-441 m³ of material per hour and reach a lifting height of 4.13-54.7 m, meeting a wide range of production needs.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Widely used in the building materials, power generation, metallurgy, machinery, chemical, mining, and other industries.

Product Introduction

The NE-type plate chain bucket elevator is a widely used vertical conveying device for vertical conveying of powders, granular, and bulk materials. It can also convey abrasive materials such as cement, sand, coal, and ceramsite sand. Material temperatures are generally below 250°C, and the lifting height can reach 40 m.

Highlights

● The entire machine adopts a fully sealed design, ensuring dust-free operation.

● The ribbed housing provides strong rigidity, high precision, and an attractive appearance.

● It can lift not only general powders, granular, and bulk materials, but also abrasive materials.

● Featuring high conveying capacity, long service life, smooth and reliable operation, easy operation and maintenance, and a compact structure.Operating Principle

The NE-type plate chain bucket elevator features a plate chain as its traction member. The hopper is fixed to the traction member at regular intervals. The traction member, via sprockets at the elevator's head and bottom, forms a closed loop system with an ascending loaded branch and a descending unloaded branch. A drive unit at the elevator's head transmits power to the traction member and hopper via the head sprocket. Material enters the elevator hopper through the feed port at the elevator's bottom. The hopper lifts the material to the head and discharges it there. Material exiting the hopper is discharged through the discharge port at the elevator's head. The elevator's hopper and traction member's head and bottom wheels are housed in a fully sealed housing, ensuring dust-free material transportation. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español