The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

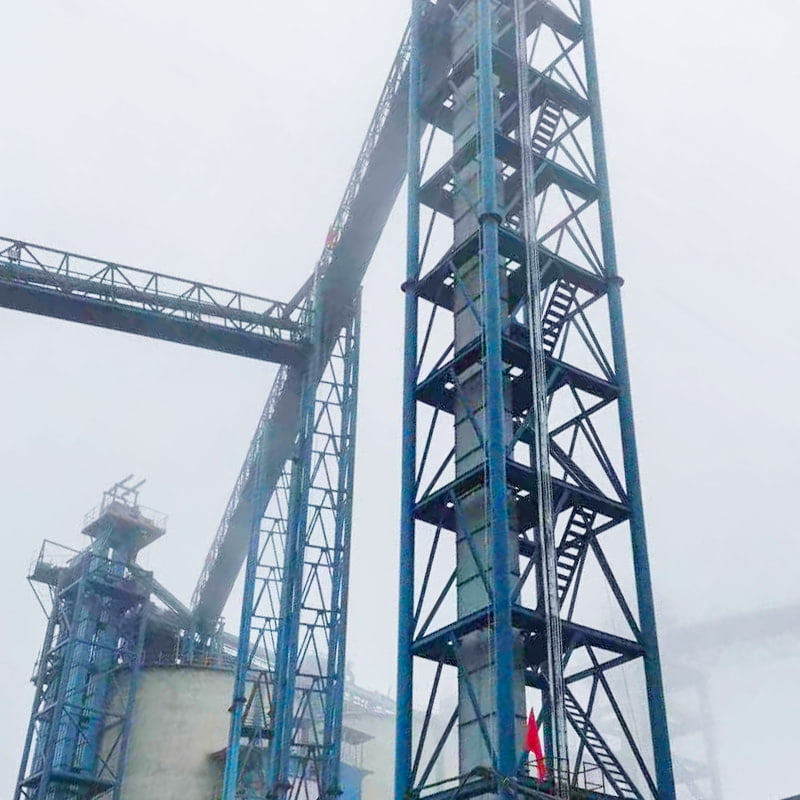

READ MORENSE Plate Chain Bucket Elevator

The NSE series high-speed plate chain bucket elevator is a new type of vertical lifting equipment developed by our company using advanced technologies from similar foreign products. It is suitable for lifting powdered and granular materials such as cement, pulverized coal, and finely crushed ore, and is widely used in industries such as building materials, metallurgy, coal, and power generation.

-

SPECIFICATIONS

-

CONTACT US

-

The NSE series plate chain bucket elevators come in more than a dozen basic models: NSE100 to NSE1900, with lifting capacities ranging from 100m³/h to 1900m³/h. Each model features a different lifting speed and hopper shape (D-type, A-type, and L-type) depending on the material being conveyed. The maximum lifting speed is ≤71m/min and the maximum lifting height is 65m. We can also design extended models with capacities between the above models based on user requirements.

Features

● Large conveying capacity

This series of elevators offers the highest conveying capacity among elevators of similar cross-sectional dimensions, with a lifting capacity of 100-1900m³/h.

● Wide Lifting Range

This type of elevator has minimal requirements for material type and properties. It can lift not only general powdered and granular materials, but also abrasive materials. The required material temperature is ≤200°C.

● Low Drive Power

This elevator utilizes inflow feeding, induction discharge, and a densely packed, large-capacity hopper arrangement. This eliminates backflow and scooping during material lifting, resulting in low reactive power and approximately 30% power savings compared to chain elevators.

● Long Service Life

The elevator utilizes inflow feeding, eliminating the need for bucket scooping, ensuring the life of the hopper. Under normal use, the conveyor chain has a service life of over three years.

● High Operational Reliability

Advanced design principles and processing methods ensure the reliability of the entire unit, making operation and maintenance easy, with a minimal number of wearing parts and a trouble-free time exceeding 20,000 hours.

● Structural Components/Operating Components

Composed of a hopper and bushing roller chain.

● Drive Unit

Composed of a main reducer, hydraulic coupling, main motor, and auxiliary reducer motor. The drive unit can be installed in either left- or right-hand positions.

Left-hand installation: The drive unit is located on the left side of the housing, facing the feed inlet.

Right-hand installation: The drive unit is located on the right side of the housing, facing the feed inlet.● Head unit

Consists of the upper housing, upper cover, and head shaft assembly.

Mid-housing: Available with a support intermediate section connected to the upper housing, an intermediate section with an inspection door, a standard intermediate section (2.5m high), and custom intermediate sections with 1m and 1.5m heights. These sections can be adjusted to different heights in 0.5m increments using a hoist.●Tail unit

Consists of the lower housing, feed inlet, tail shaft assembly, and tensioning device (optionally equipped with a level meter and speed detection switch).

-

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español