The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MOREGZ Series Electromagnetic Vibrating Feeder

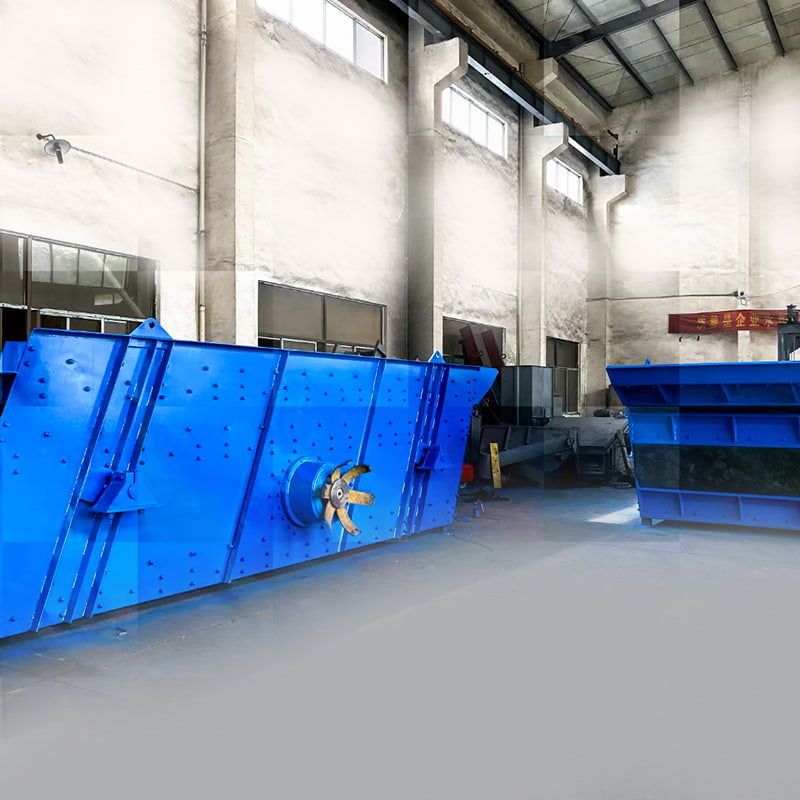

Electromagnetic vibrating feeders are used to uniformly and quantitatively feed materials from silos or other storage equipment to receiving equipment. They are essential equipment for automated assembly lines. They are designed for quantitative or continuous feeding of bulk, granular, or powdered materials. They are widely used in industries such as mining, metallurgy, coal, electric power, chemicals, glass, and refractory materials.

-

SPECIFICATIONS

-

CONTACT US

-

Application Areas

Widely used in mining, metallurgy, coal, building materials, light industry, chemicals, electric power, and machinery.

Product Introduction

The GZ electromagnetic vibrating feeder is used to uniformly and continuously feed bulk, granular, and powdered materials from silos or other storage equipment to receiving equipment. It offers stepless feed rate adjustment and automated production process control. This device features a simple structure, easy operation, requires no lubrication, and consumes low energy. It also allows for uniform feed rate adjustment.Key Advantages

● Because the material flow can be instantly changed and opened and closed, the feed rate is highly accurate.

● It features a small size, light weight, simple structure, easy installation and maintenance, and low operating costs.

● It also offers low energy consumption and minimal wear on the feed trough.

● It enables centralized and automated control of the production process.Operating Principle

The current flowing through the electromagnetic coil of the vibrator in the electromagnetic vibrating feeder is single-phase, half-wave rectified. When the coil is energized, current flows through it during the positive half-cycle, generating a pulsed electromagnetic force between the armature and the core, which attracts each other. This causes the trough to move backward, and the main spring of the vibrator deforms, storing a certain amount of potential energy. During the negative half-cycle, when no current flows through the coil, the electromagnetic force disappears, and the main spring releases its energy, causing the armature and core to move forward in the opposite direction, away from the trough. The electromagnetic vibrating feeder then reciprocates at the frequency of the AC power supply. Because the bottom plane of the trough forms a certain angle with the line of action of the excitation force, the material in the trough moves continuously forward along a parabolic trajectory. Adjusting the rectifier voltage controls the feed rate. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español