The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

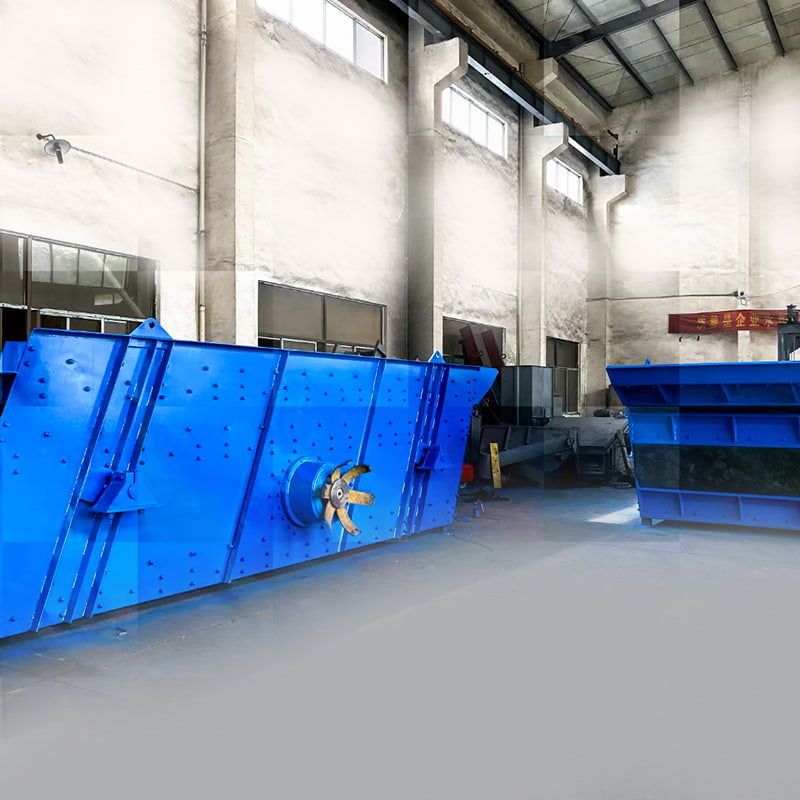

READ MOREImpeller Feeder

Rigid impeller feeder, commonly known as discharger, also called ash discharge valve. It is mainly used in dust removal and cleaning and professional conveying and batching systems in power plants, cement plants, chemical plants and other industries. It is used as air lock or quantitative feeding when conveying dry powder materials. It can also be used to discharge ash under the ash hopper of dust collector and air preheater. It has a simple structure, stable performance, easy operation and maintenance, and is an ideal accessory for conveying, unloading and batching systems.

-

SPECIFICATIONS

-

CONTACT US

-

Rigid impeller feeder is divided into three categories: ordinary type, pressure-resistant type and high-temperature resistant type. (1) Pressure-resistant type: It uses a closed rotor and can be widely used in suction-type, pressure-type air conveying systems and negative pressure conveying equipment. It can ensure that the air flow pressure in the conveying pipe does not leak and can safely convey and collect materials. Therefore, it is called a universal air lock machine in this regard. It is not only pressure-resistant, but also has the functions of ordinary type. (2) High-temperature resistant type: The temperature rise of material conveying and discharge port is different. (3) Ordinary type: It can be used for common materials below 80 degrees and at room temperature. It can continuously and evenly feed materials into the conveying pipe, and in the system and separation dust collection part, it can also serve as a discharger.

-

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español