The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MOREGZT Series Grizzly Feeder

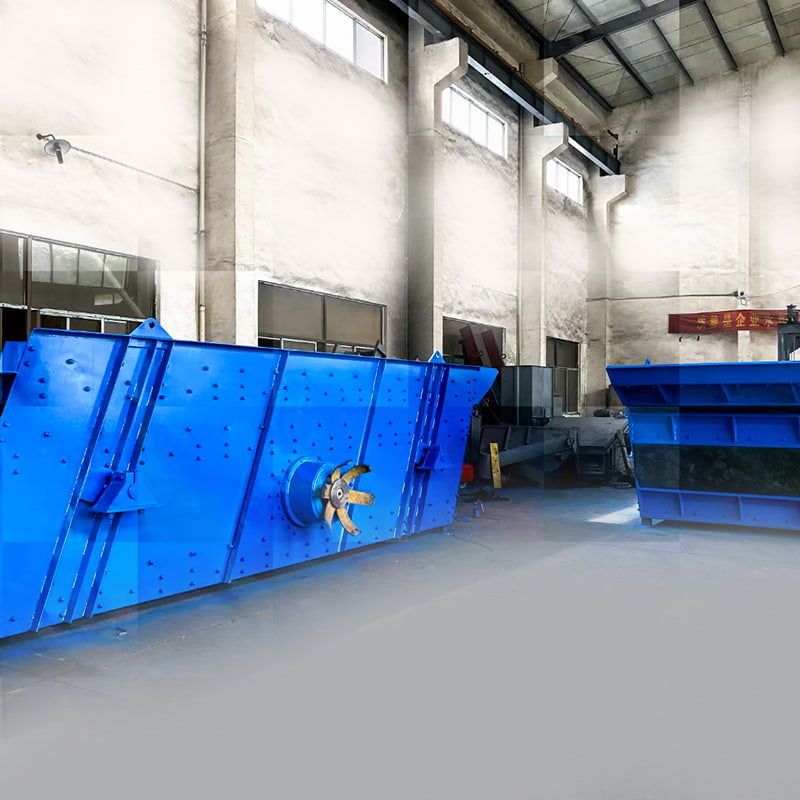

Our GZT series grizzly feeder is designed and manufactured using Swedish and Finnish technologies. It utilizes a vibrating motor manufactured with imported Japanese technology as its excitation source. It is designed for uniform feeding of bulk materials before the primary crusher. The grizzly screen also removes fine materials such as dirt, achieving pre-screening and improving primary crushing capacity. Available in four sizes, this feeder features a 10° feed angle and can meet feed requirements of 1000mm particle size and 30-600t/h.

-

SPECIFICATIONS

-

CONTACT US

-

The GZT Series grizzly vibrating feeder is a new type of feeder. It delivers uniform, timed, and continuous feeding of bulk and granular materials from the storage silo to the receiving device during the production process. In sand and gravel production lines, it provides continuous and uniform feeding of crushing machinery and performs coarse screening of materials. It is widely used in combined crushing and screening operations in industries such as metallurgy, mining, power generation, building materials, chemicals, and machinery.

Highlights

● Smooth vibration, reliable operation, and long life

● Flow rate can be varied and controlled at any time, ensuring easy and stable adjustment

● Simple structure, reliable operation, and easy adjustment and installation

● The vibration motor is the excitation source, resulting in low noise. Low power consumption and excellent adjustability.Operating Principle

The GZT series vibratory feeder primarily utilizes a pair of vibration motors with identical performance parameters as the excitation source. When the two motors rotate in opposite directions at the same angular velocity, the inertial forces generated by their eccentric masses repeatedly add or cancel each other out at specific phases, generating a powerful combined excitation force. This forces the feeder body to vibrate against the support springs. This vibration, acting as a driving force, drives the material to slide and throw within the trough, continuously moving the material forward and achieving the feeding purpose. As the material passes through the screen bars on the trough, smaller particles are able to fall through the gaps between the bars, bypassing the subsequent crushing process, achieving a screening effect. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español