The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MOREForced Feeder

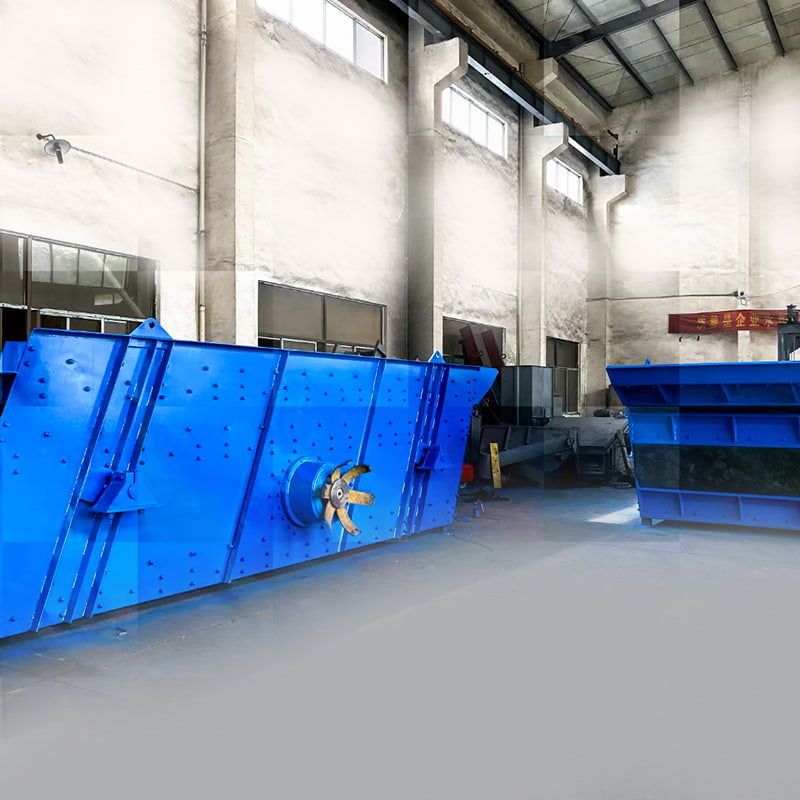

The forced feeder is a new product independently designed and developed by our company based on the characteristics of sticky materials. This product overcomes the difficulties of high-moisture materials sticking to the wall during discharge, making it an ideal device for unloading high-moisture, sticky materials in industries such as hazardous waste.

-

SPECIFICATIONS

-

CONTACT US

-

Operating Principle

The device uses forward and reverse rotation of the spiral blades and variable speeds to achieve self-cleaning and conveying, preventing sticky materials from accumulating and sticking to the wall, preventing discharge.

We can customize various specifications and models to meet customer needs.

-

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español