Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

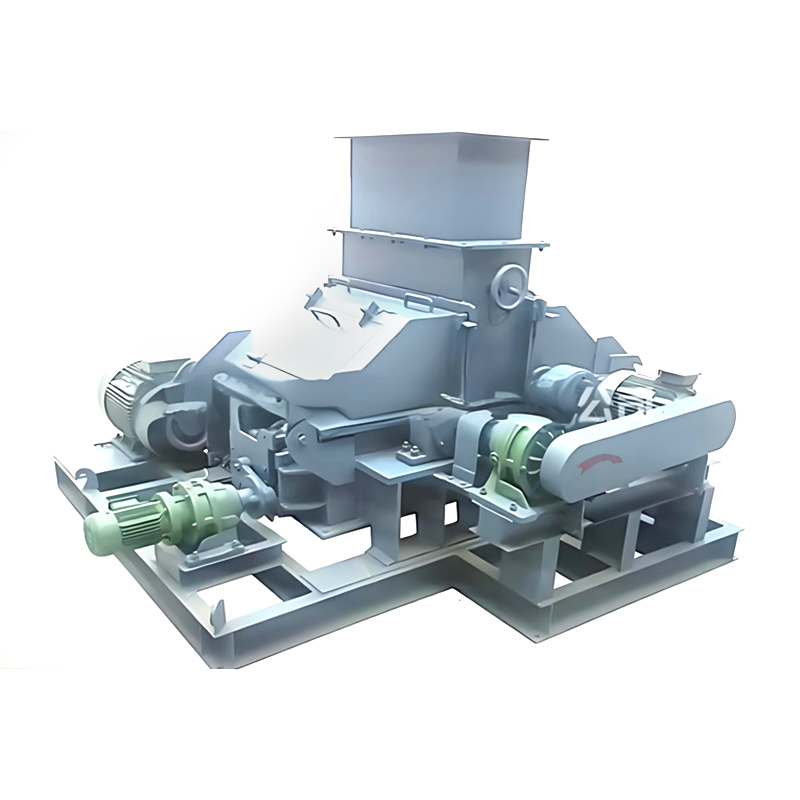

READ MOREDouble-Roller Extrusion Granulator

The double-roller extrusion granulator is a new type of equipment developed by our company based on the twin-roller extrusion granulator. It utilizes a dry-free process, produces granules at room temperature, and forms the pellets in a single operation. It boasts a wide range of raw material compatibility and is suitable not only for granulating fertilizers, feed, and chemical industries, but also for rare earth, metallurgy, coal, biological agents, and environmental protection projects. To some extent, it fills a gap in the industry, is at the forefront domestically, and is also a major environmental protection project!

-

SPECIFICATIONS

-

CONTACT US

-

The double-roller extrusion granulator operates as follows: an electric motor drives a pulley, which is then transmitted through a speed reducer to a pair of high-pressure rollers with sliding housings, which rotate relative to each other. In the DZJ-I extruder, the two rollers are driven by a set of split gears, while in the DZJ-II extruder, the two rollers are directly driven by two output shafts on a dedicated speed reducer, achieving extrusion and forming. During production, raw materials enter through a hopper, are squeezed and formed by the high-pressure rollers, and then, after demolding, flow freely into the crushing and forming chamber below the rollers. The crushing and shaping power is transmitted by a chain from the sprocket of the active pressure roller shaft to a pair of crushing rollers, which move relative to each other. Crushing and screening occur within the working chamber, and the finished granules pass through a screen into a discharge chute.

The double-roller extrusion granulator integrates granulation, forming, and screening into a single structure, resulting in an attractive appearance, simple operation, and low energy consumption. Key components, such as the rollers, are made of a new metal material that is corrosion-resistant, wear-resistant, and impact-resistant. The DZG-II model not only possesses these characteristics, but our company has also upgraded the frame, using corrosion-resistant casting as a single unit for the bearing frame, resulting in excellent stability and significantly extending the service life of the rolling bearings and main shaft. The transmission system utilizes a dual-input transmission system, which not only improves the input power ratio but also ensures lubrication and sealing of the transmission gears. This machine boasts a compact structure, excellent stability, good sealing, low noise, and easy operation and maintenance.

-

Message Feedback

-

-

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE -

The agricultural industry relies heavily on efficient and reliable fertilizer manufacturing systems to meet the growing global food demand. Among these, the Compound Fertilizer Pro...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español