The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

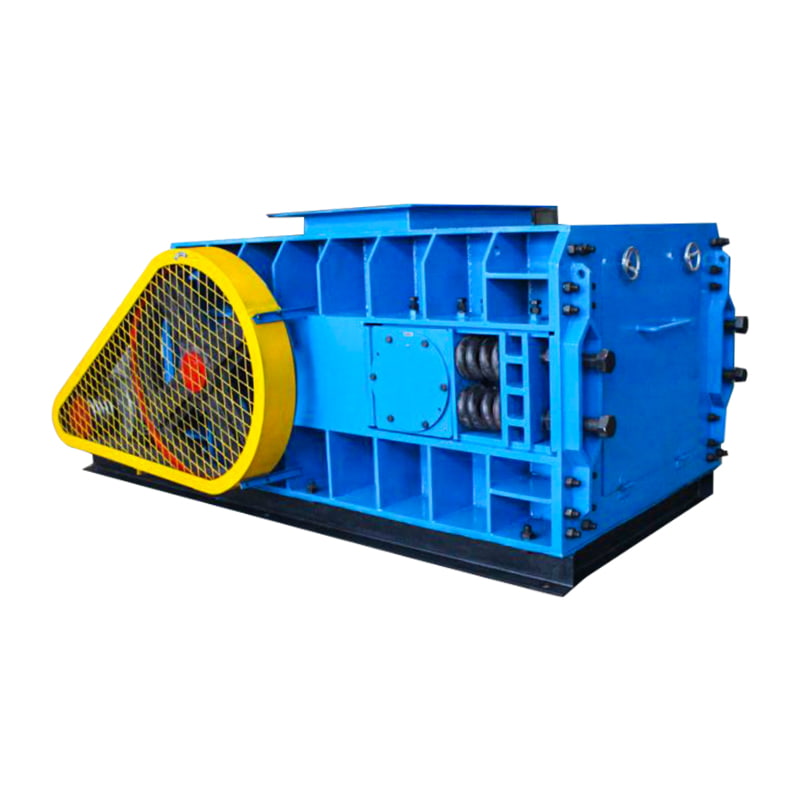

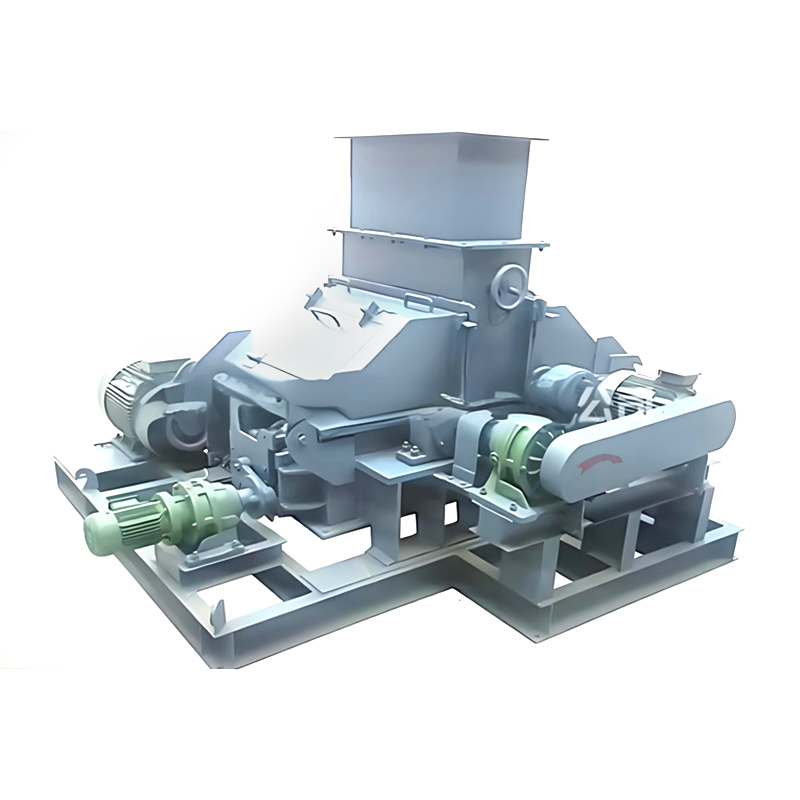

READ MOREDouble-Roller Crusher

Our double-roller crushers are available in six models based on roller diameter and length, meeting production needs with feed sizes ranging from 32mm to 90mm, discharge sizes from 2mm to 25mm, and hourly outputs from 2 to 60 tons. They feature a simple structure, compact and lightweight design, low price, reliable operation, easy crushing adjustment, minimal over-crushing, and the ability to crush sticky and wet materials.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Suitable for crushing bulk materials in the metallurgy, building materials, mining, highway, and mineral processing industries.

Product Introduction

Double-roller crushers are suitable for coarse and intermediate crushing of brittle, bulk materials in the cement, chemical, power, mining, metallurgy, building materials, refractories, and coal industries. They offer a large feed size and adjustable discharge size, and can crush materials with a compressive strength of ≤160 MPa. Especially suitable for the coal industry, this machine can crush raw coal directly after iron and impurity removal, eliminating the need for gangue removal. The crushed material has a uniform particle size and a low over-crushing rate, simplifying the coal preparation process and reducing investment and production costs.

Highlights

● Small size, high crushing ratio, high crushing capacity, low noise, simple structure, and easy maintenance.

● Uniform crushed material particle size, low over-crushing rate, easy maintenance, sensitive overload protection, and safety and reliability.

● Direct crushing in the coal industry, resulting in uniform crushing material with a low over-crushing rate.

● Simplified process, reducing investment and production costs.Operating Principle

Double-roll crushers (double-roll crushers) are suitable for coarse and intermediate crushing of brittle, bulky materials in industries such as cement, chemicals, power generation, mining, metallurgy, building materials, refractory materials, and coal. They offer a large feed size and adjustable discharge size, and can crush materials with a compressive strength of ≤160 MPa. Especially in the coal industry, this machine can be used to crush raw coal. As long as the iron and impurities are removed, there is no need to remove gangue, and the crushed material has uniform particle size and low over-crushing rate, which simplifies the coal preparation process and reduces investment and production costs. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español