The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MOREVertical Roller Mill

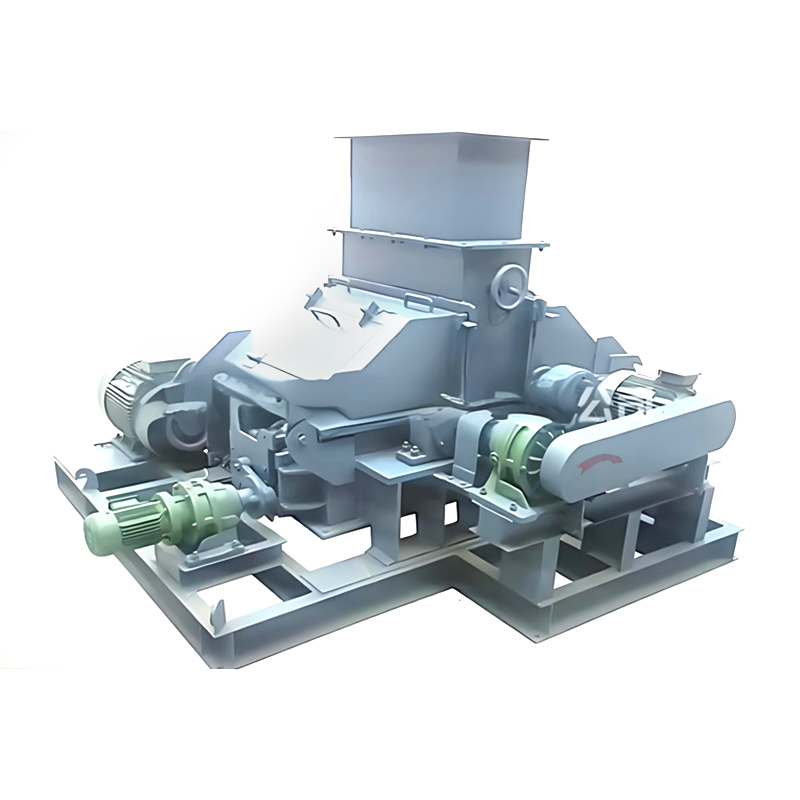

The vertical mill is an ideal large-scale grinding equipment, widely used in industries such as cement, power generation, metallurgy, chemicals, and non-metallic mining. It integrates crushing, drying, grinding, grading, and conveying, offering high production efficiency and capable of grinding lump, granular, and powdered materials into the desired powder form.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Cement, chemical, coal, and power generation industries

Product Introduction

The vertical mill, also known as a roller mill, is widely used for large-scale and ultrafine material grinding in the cement, chemical, coal, and power generation industries. It is an ideal equipment for the grinding industry, integrating crushing, drying, grinding, grading, and conveying. It can be used in coal pulverization to achieve product fineness that meets industry standards.

Key Advantages

● High grinding efficiency, low power consumption

● Simple and reliable operation, stable product quality

● Simple process flow, simultaneously completing grinding, drying, and powder selection

● Small footprint, compact layout, and low construction investmentOperating Principle

An electric motor drives the grinding disc through a reducer. Simultaneously, hot air enters the vertical mill through the air inlet. Material falls through the discharge port onto the center of the grinding disc. Centrifugal force moves the material from the center toward the edge of the grinding disc. Passing through the annular grooves on the grinding disc, it is crushed by the grinding rollers. The crushed material continues to move toward the edge of the grinding disc until it is carried away by the airflow from the air ring. Larger particles fall back onto the grinding disc for further crushing. As the material in the airflow passes through the upper separator, guide vanes pull the coarse material from the conical hopper onto the grinding disc. Fine powder exits the mill along with the airflow and is collected by the system's dust collector. The collected powder becomes the finished product of the vertical mill. Contact with the air in the housing dries the material to the desired dryness and moisture content. By adjusting the angle of the separator guide blade (not adjustable for small vertical mills) and the speed of the separator rotor, the required coarseness of the product can be achieved. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español