The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MORECoal Mill Explosion-Proof Bag Dust Collector

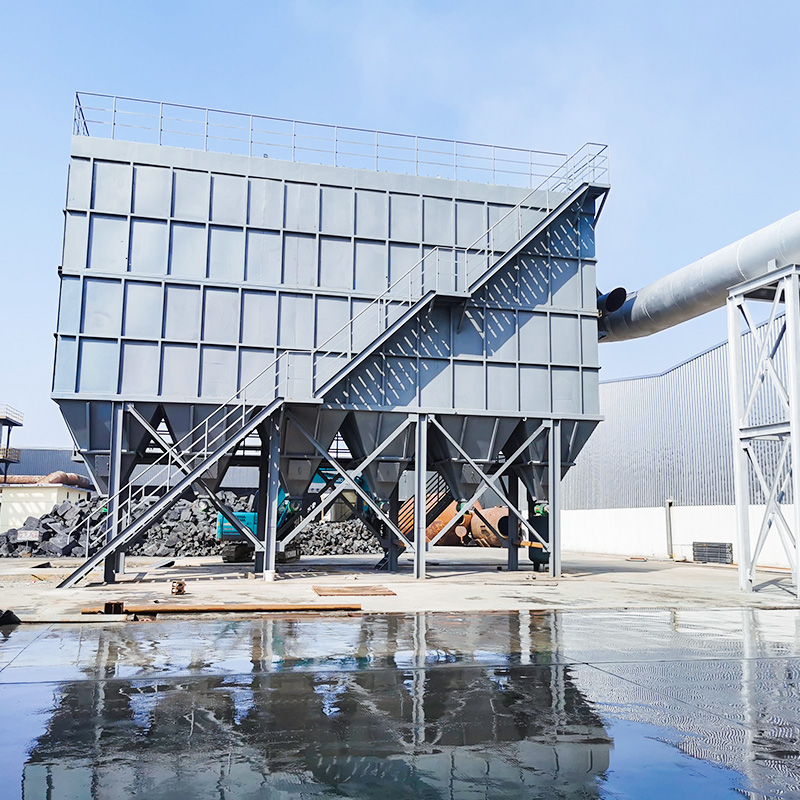

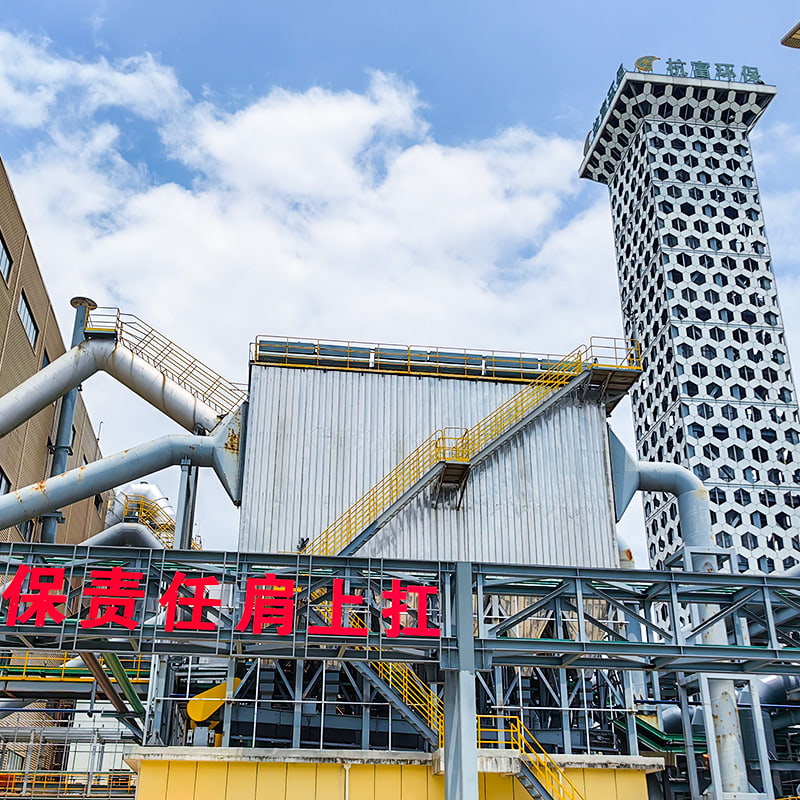

The TQMM series coal mill explosion-proof bag dust collector is a new high-performance bag dust collector developed by A.BITION (Shanghai) R&D Center based on the airbox pulse bag dust collector. It features an explosion-proof mechanism and explosion-proof valves, making it suitable for pulverized coal preparation systems and the collection of flammable and explosive dust. It utilizes an advanced, chambered, offline cleaning method to prevent re-adsorption of cleaned dust. This system features high cleaning capacity, excellent cleaning results, low system resistance, long filter bag life, and high dust removal efficiency. The entire system utilizes PLC automatic control, and parameters can be adjusted according to operating conditions.

The TQMM series dust collectors are available in various sizes, with varying numbers of chambers and filter bags. The number of bags per chamber is 32, 64, or 96, and the filter bag size is increased to 130mm x 2450mm.

-

SPECIFICATIONS

-

CONTACT US

-

TQM(M) Series Coal Mill Bag-Type Explosion-Proof Dust Collector Features

● Unique explosion-proof device completely eliminates the potential risk of explosions caused by dust removal media;

● Offline dust cleaning eliminates secondary dust generation and delivers excellent cleaning results;

● Self-locking filter bag seal ensures excellent sealing and high dust removal efficiency;

● Airbox-type structure minimizes resistance and facilitates inspection and replacement of filter bags;

● Fully automatic control for easy operation and high reliability.Structure and Working Principle of the TQMM Coal Mill Explosion-Proof Bag Dust Collector

The TQMM series air box pulse bag explosion-proof dust collector primarily consists of a base steel structure, ash hopper, upper housing, housing, air inlet and outlet, filter bags, cleaning device, and electrical control. Depending on the actual situation, ash removal devices such as a silo vibrator can be installed on the outer wall of the hopper, a star-shaped ash discharge valve, or a screw conveyor can be installed at the hopper outlet.

1. Filtration Principle

Dust-laden air enters the air inlet and passes through the hopper. Large dust particles are separated by inertia and gravity, falling directly into the bottom of the hopper. After passing through the hopper, the dust-laden air enters the filter bag filtration area in the middle housing. The air passes through the filter bags, trapping dust on their outer surfaces. The purified air enters the upper housing through the bag opening and is discharged through the air outlet.

2. Cleaning Principle

As filtration time increases, the dust layer on the filter bags accumulates, increasing the resistance of the dust removal equipment. When the resistance reaches the set value, the cleaning device begins cleaning. First, the lift valve in a chamber closes, shutting off the filtered airflow. Then, the solenoid pulse valve opens, allowing compressed air to rapidly expand within the upper chamber and flow into the filter bags, causing them to expand, deform, and vibrate. The reverse airflow then sweeps away dust adhering to the outer surfaces of the bags, removing them and allowing them to fall into the ash hopper. After cleaning is complete, the solenoid pulse valve closes, the lift valve opens, and the chamber resumes filtering. Each chamber is cleaned sequentially, with one cleaning cycle consisting of the first cleaning of one chamber and the next.

3. Dust Collection

Dust trapped by filtration and cleaning falls into the ash hopper and is then discharged from the hopper outlet.

4. Working Principle of the Explosion-Proof Device

The primary pollutant in the mill exhaust is fine-grained coal. When exposed to sparks or when the temperature rises to the flash point of the coal-air mixture, the gas can explode. Under normal circumstances, the explosion-proof valve is closed by the force of the weight, and the lever principle presses the valve plate against the valve frame with a certain force, ensuring a good airlock during normal operation. When a BAO explosion occurs, the air pressure within the dust collector rises sharply, causing the valve plate to exert an outward thrust. When this thrust overcomes the weight of the weight, the valve opens, allowing the BAO gas to be discharged from the chamber, thereby protecting the dust collector, surrounding facilities, and personnel.Features of the TQMM Coal Mill Explosion-Proof Bag Dust Collector

1. Suitable for high-concentration dust removal. The maximum inlet concentration can reach 1000g/Nm³, eliminating the need for additional dust collector equipment such as a cyclone dust collector. It can be used directly as a final dust removal device.

2. Offline cleaning technology utilizes chambered backflush pulse cleaning, eliminating the secondary dust re-entrainment and "re-adsorption" phenomenon associated with online cleaning while maintaining the equipment's normal and continuous operation. This improves cleaning efficiency and extends the life of the filter bags.

3. A self-locking filter bag seal enhances the seal between the equipment and the filter bags, improving dust removal efficiency.

4. The equipment utilizes an airbox structure, minimizing localized wear and tear and eliminating the inconvenience of inspecting and replacing filter bags.

5. The electromagnetic pulse valve utilizes a double-diaphragm structure, offering sensitive control, high efficiency, and a long service life.

6. The coal mill explosion-proof bag filter's unique explosion-proof device effectively eliminates safety hazards associated with explosions in the dust removal medium.

-

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español