The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

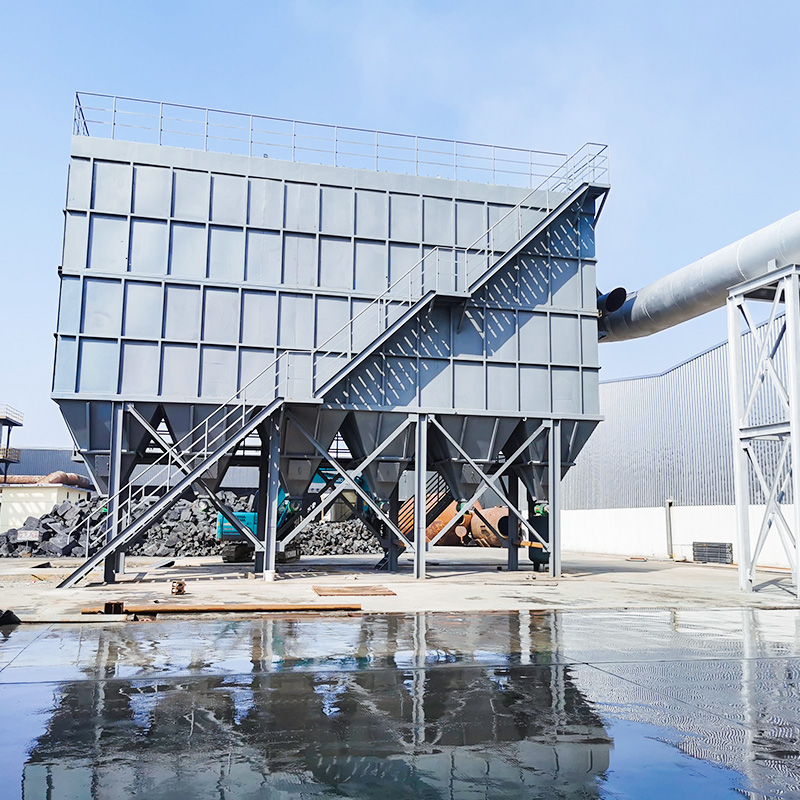

READ MOREBackflush Fiberglass Bag Dust Collector

This is a high-efficiency bag dust collector designed for high-temperature applications. It maintains high efficiency and long-term operation in high-dust flue gas conditions below 250°C, achieving a stable dust collection efficiency exceeding 99.5%. This dust collector features bottom air intake, negative pressure operation, three-state backflush cleaning, PLC-programmable timing and resistance control, and over-temperature alarm. Maintenance and bag replacement can be performed chamber by chamber without stopping the system. It is widely used in flue gas recovery applications such as cement rotary kilns, grate coolers, dryers, power plant boilers, lime kilns, metallurgical sintering machines, and electric arc furnaces.

-

SPECIFICATIONS

-

CONTACT US

-

Structural Features of the TFF Chamber Backflush Fiberglass Bag Dust Collector

1. Housing: Includes the filter bag chamber, ceiling, internal walkway, inspection door, filter bags, and hanging device.

2. Ash Hopper: Constructed of welded steel plates for a robust structure. The ash hopper is equipped with airflow deflectors and a vibrator to prevent dust from accumulating and forming bridges within the hopper.

3. Pipes and Valves: The dust collector is equipped with an inlet pipe, exhaust pipe, backflush pipe, inlet regulating valve, and other components above and below the dust collector.

4. Ash Discharge Device: An air lock valve is installed below the dust collector's hopper.

5. Backflush Cleaning Device: It consists of a three-way switching valve, settling valve, differential pressure transmitter, electrical control cabinet, solenoid valve, and compressed air piping. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español