The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MOREPE / PEX Jaw Crusher

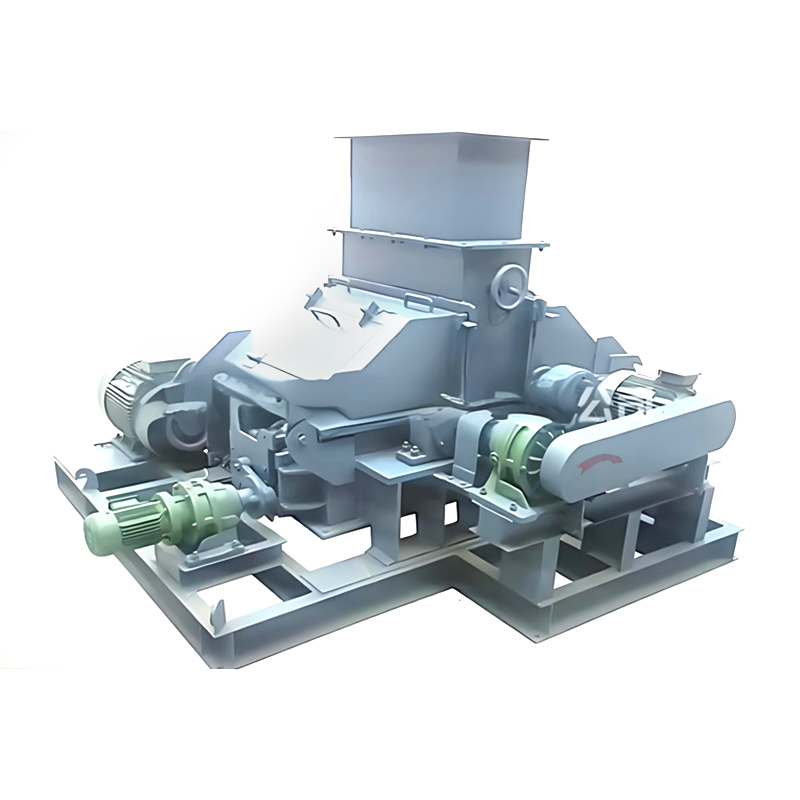

The PE / PEX Jaw Crushers are large, deep-cavity crushers with long crushing strokes, which facilitate material comminution and offer higher output compared to similar products.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

The PE series is used for coarse crushing of various ores and rocks, while the PEX series is used for secondary and tertiary crushing.

Product Introduction

The PE / PEX jaw crushers are large, compound-oscillating crushing equipment primarily designed for crushing medium-hard ores and rocks with a compressive strength not exceeding 250 MPa. They feature a high crushing ratio, high output, uniform product size, reliable operation, easy maintenance, and low operating costs. They are widely used in a wide range of industries, including mining, smelting, construction, highways, railways, water conservancy, and the chemical industry. The PE series is used for coarse crushing of various ores and rocks, while the PEX series is used for secondary and tertiary crushing.

Outstanding Advantages

● High production efficiency, high crushing ratio, uniform product particle size, low energy consumption, low noise, and low dust

● Gasket-type discharge opening adjustment device is reliable and convenient, with a wide adjustment range, increasing equipment flexibility

● Jaw plates are made of high-strength manganese steel, cast in a single operation, offering wear resistance, pressure resistance, and long service life

● Simple structure, reliable operation, low operating costs, safe and reliable lubrication system, and easy component replacementOperating Principle

The PE / PEX jaw crushers are powered by an electric motor. A belt drive drives the eccentric shaft, causing the movable jaw to reciprocate along a predetermined trajectory. This crushes the material entering the crushing chamber, which consists of a fixed jaw plate, movable jaw plate, and side guard plates. The finished material is discharged through the lower discharge opening. This series of jaw crushers adopts the flexural extrusion type of crushing. The motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw increases, thereby pushing the movable jaw plate closer to the fixed jaw plate. At the same time, the material is subjected to multiple crushing such as squeezing, splitting and bending. When the movable jaw descends, the angle between the toggle plate and the movable jaw decreases, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and spring. At this time, the crushed material is discharged from the lower opening of the crushing chamber. As the motor rotates continuously, the movable jaw of the crusher performs periodic crushing and discharging, realizing batch production. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español