The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MOREPCH Hammer Crusher

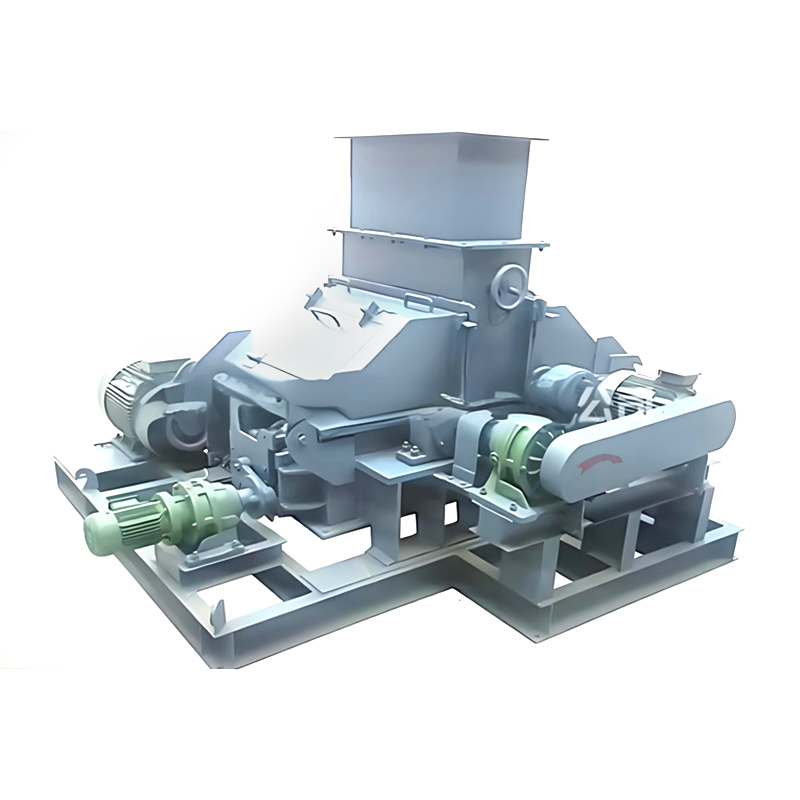

The PCH hammer crusher features smooth and reliable operation, compact structure, low dust and noise, lightweight, easy maintenance, low power consumption, and strong ability to discharge ultra-hard materials. The grate gap can be adjusted to meet the needs of different users, changing the discharge particle size. Our PCH hammer crusher is available in nine models based on rotor specifications. These models meet the crushing requirements of various brittle materials, ranging from 200mm to 400mm in feed size, 30mm or less in discharge size, and have an output of 8-1000 tons per hour.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Suitable for crushing bulk materials in industries such as metallurgy, building materials, mining, highway construction, and mineral processing.

Product Introduction

The PCH hammer crusher is suitable for crushing a variety of brittle materials, such as coal, gangue, coke, slag, red sandstone, shale, and loose limestone. The compressive strength of the material should not exceed 40 MPa, and the surface moisture content should not exceed 8%-11%. For non-cohesive materials, the surface moisture content can be controlled within 15%.

Highlights

● A large feed opening and high crushing chamber accommodate hard and large-sized materials, producing low-dust products and low power consumption.

● High-quality materials are used for vulnerable parts, such as the hammer, significantly extending the service life.

● Controllable particle size and excellent particle shape.

● Simple structure, easy maintenance and operation.Working Principle

This device is an impact rotor crusher with hammers. The hammers not only rotate with the rotor but also rotate on their own around the hammer pins. Upon entering the crusher, the material is crushed by the high-speed rotation of the hammers in the crushing chamber. The crushed material simultaneously gains kinetic energy from the hammers, rushing at high speed toward the crushing plate for primary crushing. It then falls onto the screen plate, where shearing, squeezing, and grinding by the hammers, as well as the material's collision with the crusher, further crushes the material before it is discharged through the sieve. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español