The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MOREPF Impact Crusher

Impact crushers offer high crushing efficiency, low power consumption, and uniform product particle size. They can reduce the number of crushing stages and simplify production processes, making them suitable for large- and medium-scale crushing operations. Our PF series impact crushers are available in nine models, depending on rotor specifications. They feature motors ranging from 30kW to 440kW, handle material sizes up to 950mm, and can produce up to 550t/h of material.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Suitable for crushing bulk materials in industries such as metallurgy, building materials, mining, highway construction, and mineral processing.

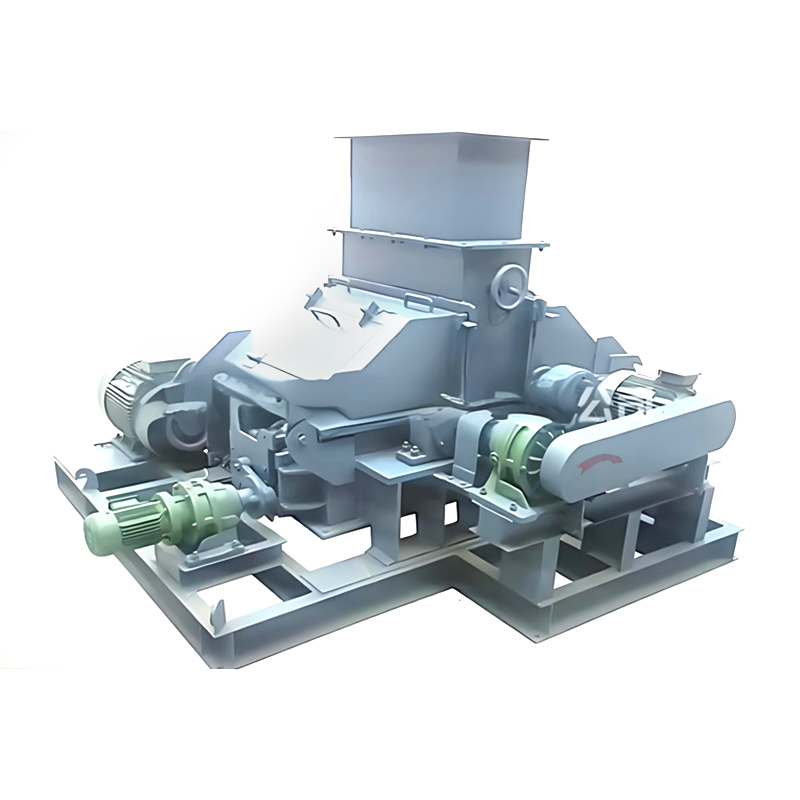

Product Introduction

The PF series impact crusher utilizes impact energy to crush brittle materials with a compressive strength of no more than 350 MPa. It offers a high crushing ratio, uniform product particle size with minimal over-crushing, low energy consumption, a wide range of particle size adjustment, and the ability to selectively crush materials. It performs both secondary and fine crushing of materials of medium hardness.

Key Advantages

● Multi-chamber uniform crushing, suitable for crushing hard rock

● Leveling plate structure ensures smaller, cubical discharge particles without internal cracks

● Low profile and large feed volume facilitate production line layout and increased feed size

● Fully hydraulically operated for easy maintenance and replacement of wearing partsOperating Principle

An impact crusher is a crushing machine that uses impact energy to crush materials. Driven by an electric motor, the rotor rotates at high speed. When the material enters the hammer action zone, it impacts with the rotor's hammers and is crushed. It is then thrown back onto the impact mechanism for further crushing. It then bounces off the impact liner and returns to the hammer action zone for further crushing. This process repeats, with the material, in descending order, entering the first, second, and third impact chambers for repeated crushing until the material is reduced to the desired particle size and discharged through the discharge port. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español