The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MOREChain Crusher

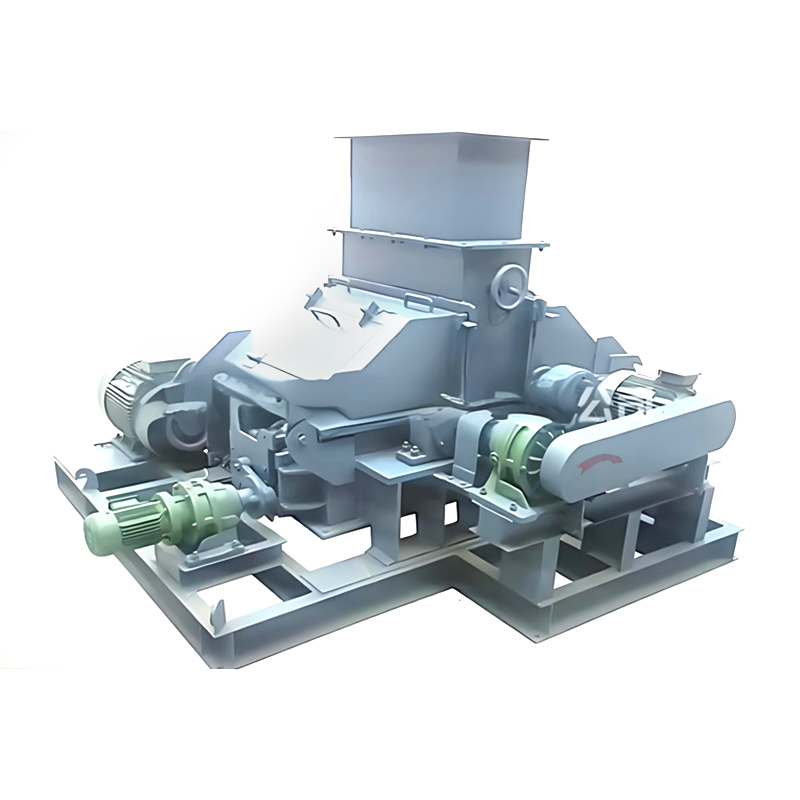

Chain crushers come in two configurations: vertical and horizontal. The vertical model features a single rotor, while the horizontal model has twin rotors. They are suitable for crushing bulk materials in the production of organic fertilizers and compound fertilizers, and are also widely used in the chemical, building materials, and mining industries. The crushing process utilizes high-strength, wear-resistant carbide chains that rotate synchronously. The inlet and outlet are strategically designed, ensuring uniform crushing, preventing sticking, and facilitating cleanup. The crusher utilizes new technology, high-quality steel, and an optimized system design, resulting in high throughput and high reliability.

-

SPECIFICATIONS

-

CONTACT US

-

The chain crusher's main working component is a rotor with a steel chain. One end of the chain is connected to the rotor, while the other end features a wear-resistant steel chain head. This is an impact crusher, crushing bulk materials through the impact of the high-speed rotating chain. When the machine is started, the motor drives the rotor at high speed, and the chain moves at high speed, creating a powerful crushing zone. After entering the crushing chamber, the material is rapidly crushed by the high-speed impact and shearing of the chain, as well as by the collision between the material and the inner wall of the equipment.

This machine features a rational structure, fast feeding, stable performance, and strong impact resistance. It can be widely used to crush fibrous materials such as leaves, bagasse, shredded bamboo, wood chips, and waste paper, as well as hard materials such as broken bricks, tiles, gravel, and coal slag. It does not affect the crushing effect on soft and hard materials. Compared with traditional crushing equipment, the chain crusher's innovative structure and energy-saving design significantly shorten the crushing time, improve the crushing efficiency, and reduce energy consumption. The overall design is easy to clean and maintain. Regular inspection of the chain and wear-resistant parts is required to ensure long-term stable operation of the equipment.

-

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español