The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

READ MORESemi-Wet Material Crusher

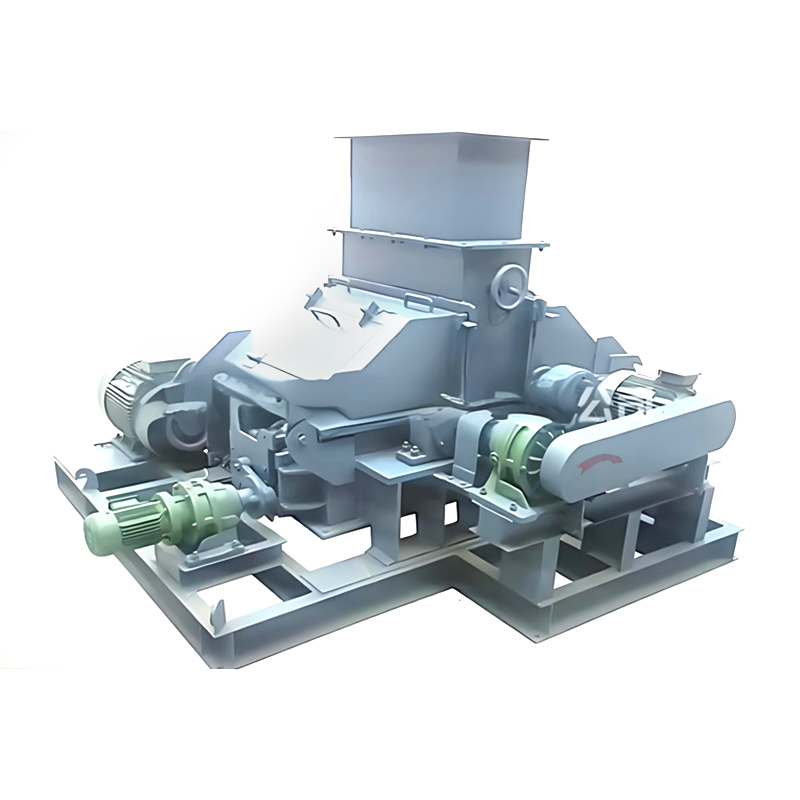

The semi-wet material crusher, available in both horizontal and vertical configurations, is a specialized crushing machine specifically designed for crushing high-moisture, fibrous materials. It solves the problem of high-moisture organic materials being difficult to crush. The machine has a moisture tolerance of 25-50% for bio-fermented organic fertilizer materials, making it suitable for processing high-moisture materials such as chicken manure, medicinal residue, and various minerals. It is an essential piece of equipment for fertilizer production and processing units.

-

SPECIFICATIONS

-

CONTACT US

-

The semi-wet material crusher frame is welded from high-quality carbon steel plates and channel steel, and has passed strict product certification and specific process requirements. Its rotor structure is innovative and rationally designed, utilizing two sets of upper and lower rotor blades for crushing, achieving twice the crushing efficiency of other products. Material enters the crushing chamber from the feed inlet, where it is continuously ground by the dual-stage blades and crushing plates until it reaches the desired granulation level. The crushing plates are adjustable, allowing the distance between the crushing plates and rotor blades to adjust the crushing fineness and yield. The machine also utilizes a flexible belt drive. The motor drives a pulley and belt, directly transmitting force to the main shaft, which rotates at high speed to achieve the desired crushing effect.

The semi-wet material crusher is suitable for a wide range of applications, including livestock and poultry manure, kitchen waste, agricultural waste, forestry byproducts, food industry waste, and bioenergy feedstock. Its screenless design allows the equipment to handle materials of varying moisture levels, effectively crushing both dry and wet materials. The complete machine can be easily operated and installed by one person, making it a crucial component of organic fertilizer production lines.

-

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español