The Compound Fertilizer Production Line is a critical solution for modern agriculture, offering high efficiency, flexibility, and scalability. Its ability to adapt to various raw m...

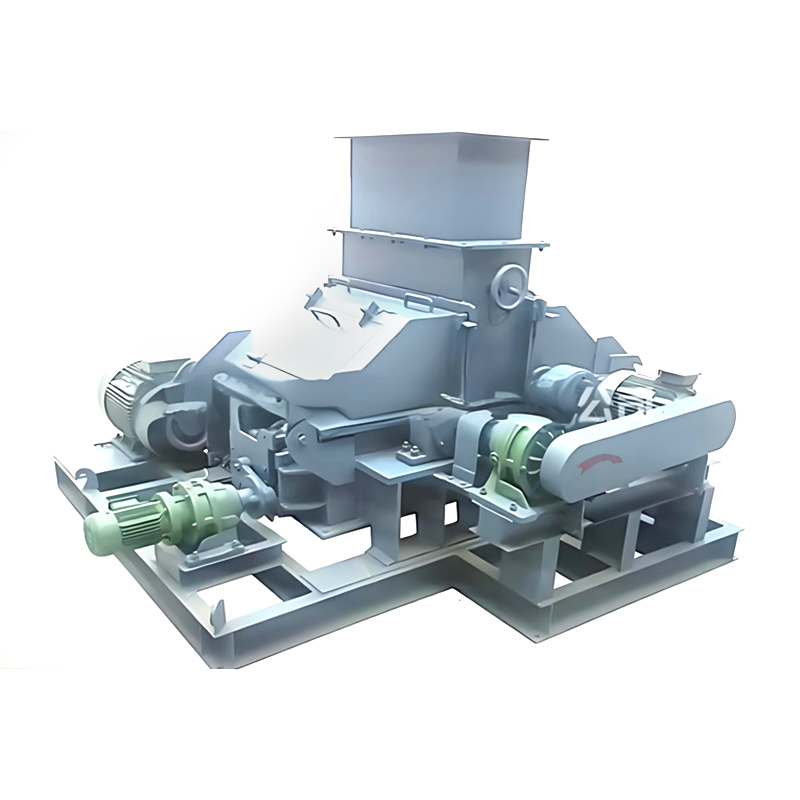

READ MOREPC Hammer Crusher

Hammer crushers, also known as hammer crushers, are available in seven models. They can crush materials ranging from 200mm to 300mm in size, with output particles smaller than 30mm. The size can be adjusted via the discharge grate, with an hourly capacity of 8-100 tons, meeting a variety of crushing needs.

-

SPECIFICATIONS

-

CONTACT US

-

Applications

Suitable for crushing bulk materials in industries such as metallurgy, building materials, mining, highways, and mineral processing.

Product Introduction

Hammer crushers, also known as hammer crushers, are the ideal equipment for small sand and gravel production lines requiring low investment and quick results. By adjusting the discharge grate pattern, selective discharge is possible.

Key Advantages

● Simple structure, easy operation and maintenance, high crushing ratio, minimal over-crushing, and uniform product particle size

● Suitable for crushing brittle, medium-hard materials with a compressive strength of 150 MPa

● Particle size can be adjusted according to customer requirements

● Attractive overall design, compact structure, few wearing parts, and easy maintenanceOperating Principle

A hammer crusher primarily relies on impact energy to crush materials. During operation, the motor drives the rotor at high speed, causing material to enter the crusher chamber evenly. The high-speed rotating hammers impact, shear, and tear the material, crushing it. Simultaneously, the material's own gravity propels it from the high-speed rotating hammers toward the baffles and screen bars within the frame. Material larger than the screen mesh size is retained on the screen plates, where it continues to be struck and ground by the hammers until it is reduced to the desired output size and discharged through the screen plates. -

Message Feedback

-

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can signif...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding ho...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves ...

READ MORE

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español