- Compound Fertilizer Production Line

- Grinding Equipment

- Material Feeding Equipment

- Dust Collection Equipment

- Drying Equipment

- Conveying Equipment

- Elevating Equipment

- Crushing Equipment

- Screening Equipment

- Industrial Mixing and Agitation Equipment

- Granulation Equipment

- Calcination Equipment

- Cooling Equipment

- Bulk and Packaging Equipment

Drying Equipment Supplier

Drying equipment, a crucial material handling device in industrial production, is widely used in a variety of industries, including mining, environmental protection, and energy. Its core function is to remove excess moisture from materials through a rational heat source supply and efficient heat exchange, ensuring that the materials meet the required moisture content for subsequent processing, storage, or discharge. This provides critical support for the smooth operation of production processes and efficient resource utilization across various industries.

Drying equipment in this category is precisely categorized based on the characteristics, form, and processing requirements of the materials being processed in different industries. Each type of equipment undergoes targeted technical research and development and structural design to adapt to the drying process requirements of specific materials. Whether targeting specific granular, paste-like, or slurry-like materials, each type of drying equipment is designed to maximize the retention of the material's active ingredients while ensuring drying efficiency or meet the specific requirements of subsequent processing. This achieves specialized, efficient, and energy-saving drying of materials in various applications, providing powerful equipment support for enterprises to address excessive moisture content and improve production efficiency.

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can significantly impact production output, quality, and overall operational costs. Understanding these factors is crucial for man...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding how to calculate and select the right capacity is essential for manufacturers looking to meet market demand while maintain...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves evaluating the physical space, technical infrastructure, environmental factors, and ensuring compliance with regulations...

READ MORE

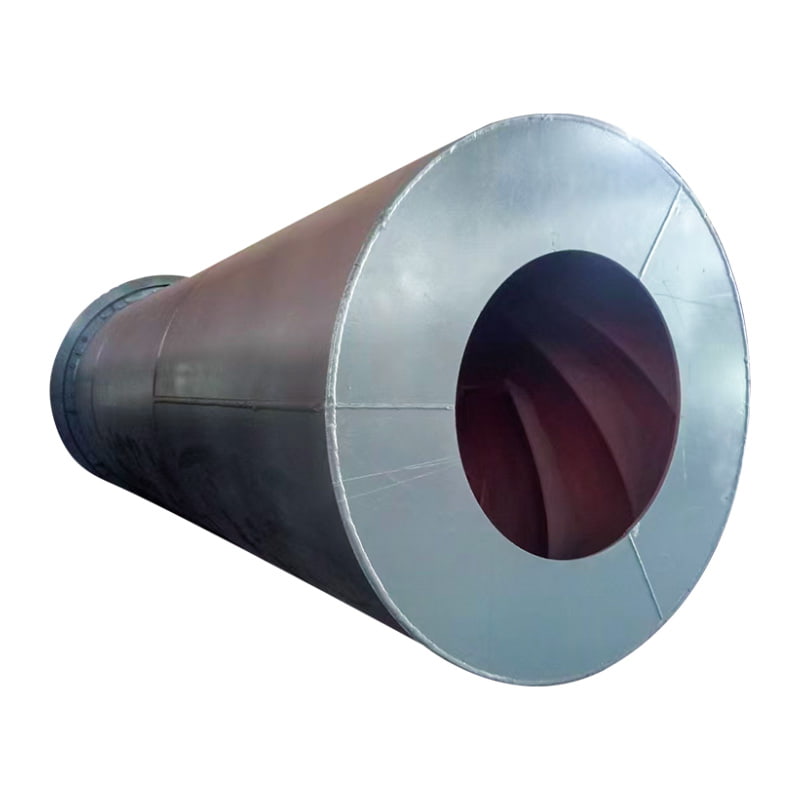

Drying equipment is a critical category of industrial machinery designed to remove moisture from raw materials or products efficiently. This category includes various types of dryers, such as rotary dryers, drum dryers, fluidized bed dryers, and belt dryers. These machines share core functions of heat transfer, moisture removal, and material handling, making them essential in fertilizer production, building materials processing, and chemical manufacturing. Drying equipment is engineered to provide stable drying performance, energy efficiency, and adaptability to different material types.

Principles of Drying Equipment

-

Rotary Dryers: Operate by rotating a drum through which hot air passes. Moisture is removed via direct or indirect heat transfer, suitable for granular or powdery materials.

-

Drum Dryers: Utilize rotating drums with heated surfaces. Materials spread thinly on the drum surface, and moisture evaporates quickly, making them ideal for slurry materials.

-

Fluidized Bed Dryers: Materials are suspended in a hot airflow, forming a fluidized bed for rapid and uniform drying. Often applied in fertilizers and chemical powders.

-

Belt Dryers: Materials are placed on perforated belts and exposed to hot air. This method provides gentle drying for heat-sensitive materials.

Applications and Case Examples

Drying equipment is widely applied in fertilizer production lines, including compound fertilizers, organic fertilizers, and bulk blending fertilizers (BB fertilizers). For example:

-

A rotary dryer in a BB fertilizer plant can process large volumes of mixed fertilizers while maintaining uniform moisture content.

-

Fluidized bed dryers are often used for granulated potassium sulfate to ensure consistent drying without material degradation.

-

Belt dryers can handle heat-sensitive organic fertilizers, maintaining nutrient integrity during drying.

Comparison of Dryer Types

| Dryer Type | Material Suitability | Energy Efficiency | Maintenance Complexity | Typical Application |

|---|---|---|---|---|

| Rotary Dryer | Granular/powder | Medium | Medium | Fertilizers, minerals |

| Drum Dryer | Slurry/paste | Medium | Medium-High | Compound fertilizers, chemical powders |

| Fluidized Bed Dryer | Fine granules | High | High | Granulated fertilizers, chemical powders |

| Belt Dryer | Heat-sensitive | Medium-High | Medium | Organic fertilizers, specialty chemicals |

Maintenance Guidelines

Proper maintenance of drying equipment ensures long-term reliability and optimal drying performance:

-

Routine Cleaning: Remove dust, residual materials, and air blockages to maintain airflow and heat efficiency.

-

Lubrication: Regularly lubricate bearings, gears, and moving parts to reduce wear.

-

Inspection: Check for drum alignment, belt tension, and sealing conditions to prevent material loss.

-

Component Replacement: Monitor wear on critical components such as heating tubes, fans, and blades, replacing them as needed.

Nantong Alisen Environmental Protection Technology Co., Ltd. provides a comprehensive range of drying equipment tailored to industrial applications. Since 2007, the company has been committed to designing and manufacturing drying systems for fertilizer and building materials production. Its dryers are integrated into complete production lines for compound fertilizers, organic fertilizers, and potassium sulfate, ensuring consistent performance and operational efficiency.

FAQ (Drying Equipment)

-

Q: How do I choose the right dryer for my material?

A: Consider material type, moisture content, heat sensitivity, and production capacity. Rotary dryers are ideal for bulk granular materials, while belt dryers suit heat-sensitive products. -

Q: What is the typical lifespan of industrial dryers?

A: With proper maintenance, dryers can operate efficiently for 10–15 years. Key factors include material abrasiveness, operating temperature, and maintenance frequency. -

Q: Can these dryers be integrated with existing production lines?

A: Yes. Drying equipment from Nantong Alisen is designed for flexible integration with compound fertilizer, organic fertilizer, and BB fertilizer lines.

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español