- Compound Fertilizer Production Line

- Grinding Equipment

- Material Feeding Equipment

- Dust Collection Equipment

- Drying Equipment

- Conveying Equipment

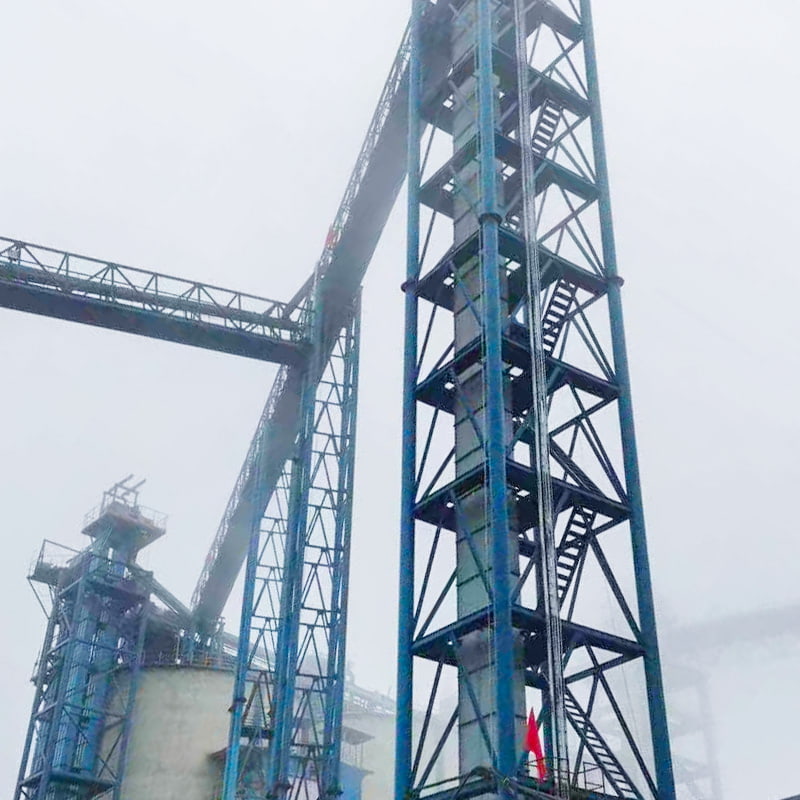

- Elevating Equipment

- Crushing Equipment

- Screening Equipment

- Industrial Mixing and Agitation Equipment

- Granulation Equipment

- Calcination Equipment

- Cooling Equipment

- Bulk and Packaging Equipment

Elevating Equipment Supplier

Elevating Equipment is a critical piece of equipment responsible for vertical or steeply inclined material transport in industrial production. It is widely used in industries such as mining, building materials, chemicals, grain, coal, metallurgy, and power generation. It serves as a core link connecting upstream and downstream production processes and enabling efficient material transfer. It overcomes height limitations and operates continuously and stably, precisely transporting materials in various forms, such as granules, powders, and small lumps, from low locations to higher silos, production lines, or downstream processing equipment. This not only significantly improves production automation and overall efficiency, but also reduces the costs and safety risks associated with manual intervention, providing crucial support for the smooth operation of various industrial operations.

In terms of design and application adaptability, elevating equipment offers strong customization capabilities. It can be tailored to the physical properties of the material being transported (such as bulk density, abrasiveness, temperature, and humidity) and conveying requirements (such as lifting height, throughput, and operating environment). Different drive modes, hopper structures, and sealing designs can be employed to ensure reliable operation under various operating conditions. At the same time, its selection needs to be closely integrated with industry characteristics and specific production needs: for light transportation in small and medium-sized scenarios, there are models with compact structure and smooth operation to choose from; for medium and high abrasive materials or harsh working conditions, there are models that are wear-resistant and resistant to extreme environments; and for the large-scale and ultra-high-rise transportation needs of large enterprises, there are also heavy-duty models with high load capacity and large flow to meet them, fully covering the diversified material transfer needs of different industries.

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can significantly impact production output, quality, and overall operational costs. Understanding these factors is crucial for man...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding how to calculate and select the right capacity is essential for manufacturers looking to meet market demand while maintain...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves evaluating the physical space, technical infrastructure, environmental factors, and ensuring compliance with regulations...

READ MORE

Elevating Equipment is widely used in fertilizer production, building materials processing, and various bulk material handling systems. As part of continuous conveying systems, Elevating Equipment ensures stable vertical transportation of granules, powders, and mixed materials, supporting automated production lines with consistent throughput and controlled material flow. In relevant projects designed or supplied by Nantong Alisen Environmental Protection Technology Co., Ltd., elevating solutions are commonly applied in compound fertilizer lines, organic fertilizer lines, BB fertilizer systems, and building materials plants, forming an essential link between crushing, mixing, drying, granulating, cooling, and packaging stages.

1. Working Principles of Elevating Equipment

Different types of elevating systems share the goal of moving materials vertically, but they operate based on distinct mechanisms:

● Bucket Elevator Principle

-

Materials enter the inlet hopper, are picked up by uniformly spaced buckets, and are lifted along a vertical casing.

-

Power is transmitted through a head pulley or sprocket, discharging materials via centrifugal or gravity methods.

-

Suitable for powders, small granules, and non-sticky materials.

● Chain Elevator Principle

-

Utilizes steel chains to drive buckets; designed for heavy-duty or high-temperature materials.

-

Ensures stable operation with high tensile strength and extended service life.

● Belt Elevator Principle

-

Uses rubber belts or reinforced belts to drive buckets.

-

Offers smooth operation and lower noise, suitable for light to medium materials.

2. Typical Application Scenarios

Elevating Equipment is commonly implemented in:

-

Compound fertilizer production lines: for feeding raw materials into granulators or distributing finished granules to cooling and screening equipment.

-

Organic fertilizer systems: for lifting fermented and crushed materials into metering or mixing equipment.

-

Bulk blending (BB) fertilizer lines: for vertical transfer of blended materials before packaging.

-

Building materials plants: transporting cement, sand, fly ash, limestone powder, or gypsum.

-

Chemical and mining industries: lifting non-abrasive or moderately abrasive materials.

Projects supported by Nantong Alisen Environmental Protection Technology Co., Ltd. often integrate elevating systems with rotary kilns, dryers, granulators, and dust collectors to form complete automated production lines.

3. Comparative Analysis of Elevating Equipment Types

| Type | Suitable Materials | Advantages | Limitations | Typical Use |

|---|---|---|---|---|

| Bucket Elevator | Granules, powders | High lifting height, sealed operation | Not ideal for sticky materials | Fertilizer particles, powders |

| Belt Elevator | Light to medium materials | Smooth operation, low noise | Belt wear under heavy load | Building materials, feed mills |

| Chain Elevator | Heavy, hot, abrasive materials | High strength, long life | Higher maintenance cost | Cement plants, chemical materials |

4. Key Performance Features

-

Stable vertical conveying for continuous production.

-

Compact structure suitable for limited installation spaces.

-

Dust-controlled design supporting environmental protection standards.

-

High conveying capacity to match large-scale production lines.

-

Compatible with upstream and downstream fertilizer machinery supplied by Nantong Alisen Environmental Protection Technology Co., Ltd.

5. Maintenance Guidelines

To ensure safe, efficient, long-term operation:

Routine Inspection

-

Check bucket fastening points and belt/chain tension weekly.

-

Inspect inlet and discharge ports for wear or obstruction.

Lubrication

-

Lubricate bearings, sprockets, and chains according to manufacturer intervals.

Alignment & Tension Adjustment

-

Maintain belt alignment to prevent edge wear.

-

Adjust chain tension to avoid skipping or overloading.

Wear Part Replacement

-

Replace worn buckets, belts, or chains before failure.

-

Inspect casing and head section for friction-induced wear.

6. FAQs for Elevating Equipment

Q1: How to select the right Elevating Equipment for my material?

Choose equipment based on material density, abrasiveness, particle size, flowability, and temperature.

Q2: Can Elevating Equipment handle sticky or moist materials?

Standard bucket elevators are not suitable; chain-type or specially coated buckets may be used depending on the material.

Q3: What is the typical lifting height?

Common lifting heights range from 3–40 meters depending on model specifications.

Q4: How is Elevating Equipment integrated into a fertilizer production line?

It is positioned between mixers, granulators, dryers, coolers, or packaging machines to achieve continuous vertical transfer.

Q5: What industries commonly use this equipment?

Fertilizer, building materials, chemical processing, mining, and agricultural storage.

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español