- Compound Fertilizer Production Line

- Grinding Equipment

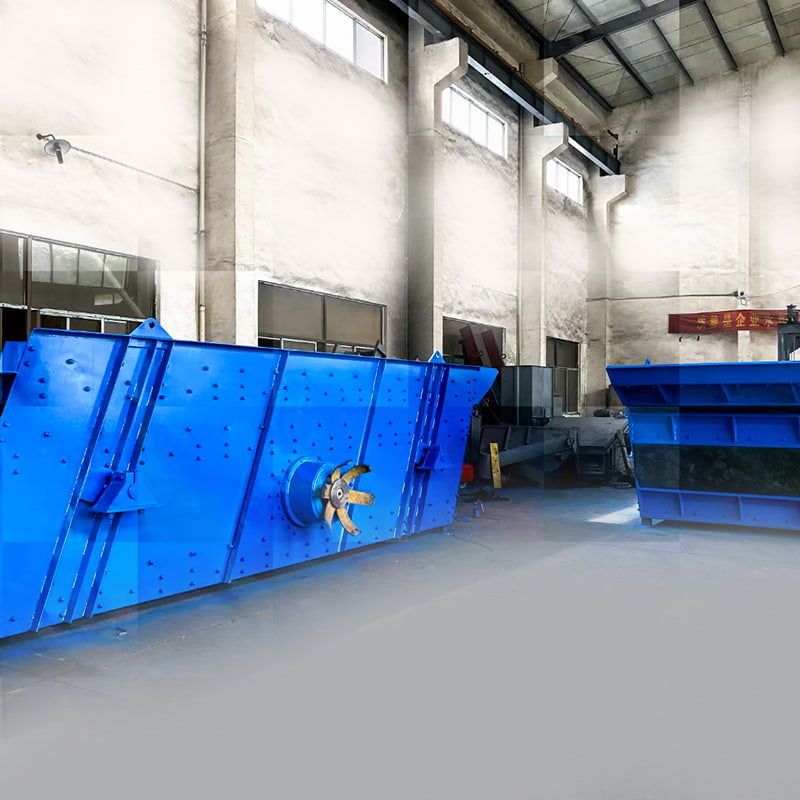

- Material Feeding Equipment

- Dust Collection Equipment

- Drying Equipment

- Conveying Equipment

- Elevating Equipment

- Crushing Equipment

- Screening Equipment

- Industrial Mixing and Agitation Equipment

- Granulation Equipment

- Calcination Equipment

- Cooling Equipment

- Bulk and Packaging Equipment

Material Feeding Equipment Supplier

Material Feeding Equipment is an essential component of industrial production and material handling processes. It's primarily used to stably and evenly convey various bulk, granular, or powdered materials at a specific rate and pattern to subsequent processing, handling, or storage equipment. This type of equipment is widely used in industries such as mining, metallurgy, building materials, chemicals, grain processing, and the power industry. Depending on material characteristics (such as hardness, moisture, and particle size) and production requirements, it can be categorized into vibrating feeders, screw feeders, belt feeders, disc feeders, and electromagnetic vibrating feeders. For example, vibrating feeders use vibration to continuously move material along a trough, making them suitable for feeding bulk or granular materials. Screw feeders, on the other hand, propel material through the rotation of spiral blades, making them ideal for conveying powdered or small particles. They also offer closed-loop conveying, reducing dust pollution.

In terms of its purpose and function, the core function of material feeding equipment is to ensure continuous and controllable material transportation, thereby coordinating the production rhythm of upstream and downstream processes and improving overall production efficiency. On the one hand, it can precisely adjust the feed rate based on the processing capacity of downstream equipment, avoiding production interruptions caused by material accumulation or insufficient supply. For example, in a mineral processing line, a vibrating feeder can evenly feed the crusher to ensure stable crushing operations. On the other hand, some material feeding equipment also has the function of preliminary screening or mixing materials. For example, a vibrating feeder with a screen can remove large impurities during the feeding process, improving the purity of the material for subsequent processing. In addition, by combining automated control with material feeding equipment, remote control and intelligent speed regulation can be achieved, further adapting to the flexibility requirements of modern production lines and reducing the cost of manual intervention.

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can significantly impact production output, quality, and overall operational costs. Understanding these factors is crucial for man...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding how to calculate and select the right capacity is essential for manufacturers looking to meet market demand while maintain...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves evaluating the physical space, technical infrastructure, environmental factors, and ensuring compliance with regulations...

READ MORE

Material Feeding Equipment is a critical component in modern fertilizer and building materials production lines. These devices are designed to ensure precise, continuous, and uniform feeding of raw materials into downstream processing equipment. Commonly used across various industries, Material Feeding Equipment includes screw feeders, belt feeders, vibrating feeders, and hopper feeders, all of which share the core functions of material transport, flow regulation, and capacity control. The equipment’s design emphasizes stable operation, high feeding accuracy, and compatibility with multiple types of raw materials, ranging from powders and granules to bulk solids.

In terms of application, Material Feeding Equipment is widely utilized in compound fertilizer, organic fertilizer, bulk blending fertilizer (BB fertilizer), and other chemical fertilizer production lines. It supports complete production processes by integrating seamlessly with crushers, granulators, dryers, coolers, coating machines, and conveyors. For example, in a rotary drum granulation line, feeders regulate the raw material input to maintain consistent granule quality, while in building materials machinery, feeders enable uniform delivery of aggregates, cement, or powders to mixers and kilns.

When comparing different feeding systems, screw feeders are preferred for precise volumetric control, belt feeders offer large-capacity handling with smooth material flow, and vibrating feeders are suitable for high-speed, high-capacity applications. Selection depends on material characteristics, production scale, and process requirements.

Material Feeding Equipment also interacts with auxiliary systems, including dust collectors and weighing systems, to improve operational safety and efficiency. Proper maintenance, such as regular inspection of screws, belts, and vibration motors, is critical to avoid blockages, material segregation, and uneven feeding, ensuring production stability.

Founded in 2007, Nantong Alisen Environmental Protection Technology Co., Ltd. is located in Qutang Town Industrial Park, Haian City, Jiangsu Province. As a technology-oriented company specializing in fertilizer machinery and building materials machinery, we design and manufacture a wide range of equipment including feeders, rotary kilns, drum granulators, crushers, dryers, coolers, coating machines, conveyors, and dust collectors. Our Material Feeding Equipment is widely adopted by major chemical fertilizer manufacturers and supports efficient operation in complete fertilizer production lines for compound fertilizers, organic fertilizers, bulk blending fertilizers, potassium sulfate, and other products.

For industry users, frequently asked questions include:

-

Q: How do I select the appropriate feeder for my raw materials?

A: Consider material type, particle size, moisture content, feeding capacity, and downstream equipment requirements. -

Q: How can I maintain consistent feeding accuracy?

A: Regular calibration, routine inspection of moving parts, and proper adjustment of speed and angle are essential. -

Q: Can feeders handle abrasive or sticky materials?

A: Yes, but special designs with wear-resistant surfaces or anti-clogging features are recommended.

In conclusion, Material Feeding Equipment plays a foundational role in maintaining production line efficiency, ensuring uniform material distribution, and enabling high-quality output in fertilizer and building material manufacturing. With the expertise of Nantong Alisen Environmental Protection Technology Co., Ltd., users can access reliable and industry-standard feeding solutions tailored to various production needs.

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español