- Compound Fertilizer Production Line

- Grinding Equipment

- Material Feeding Equipment

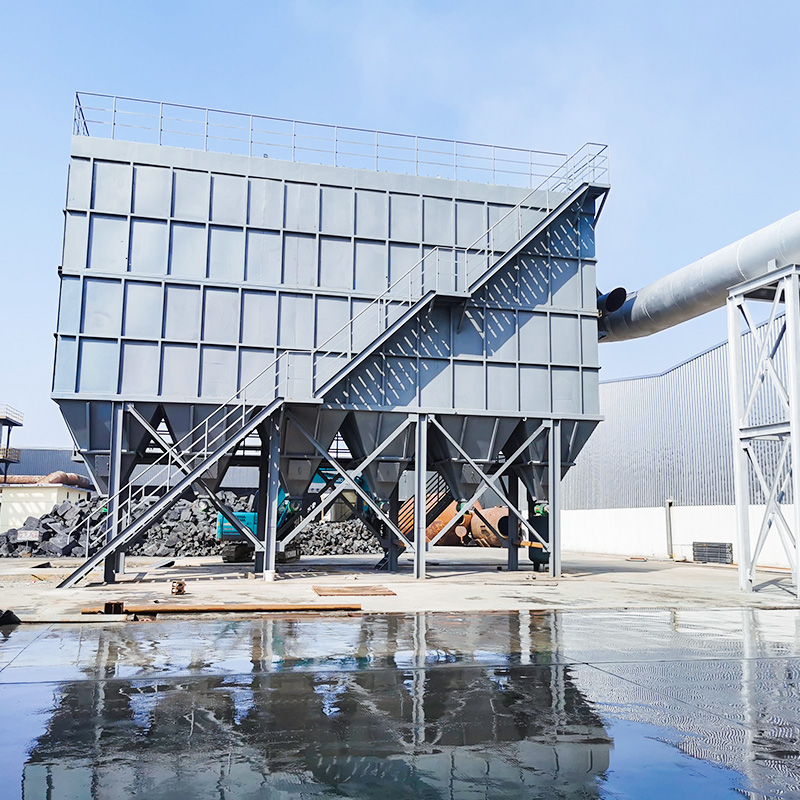

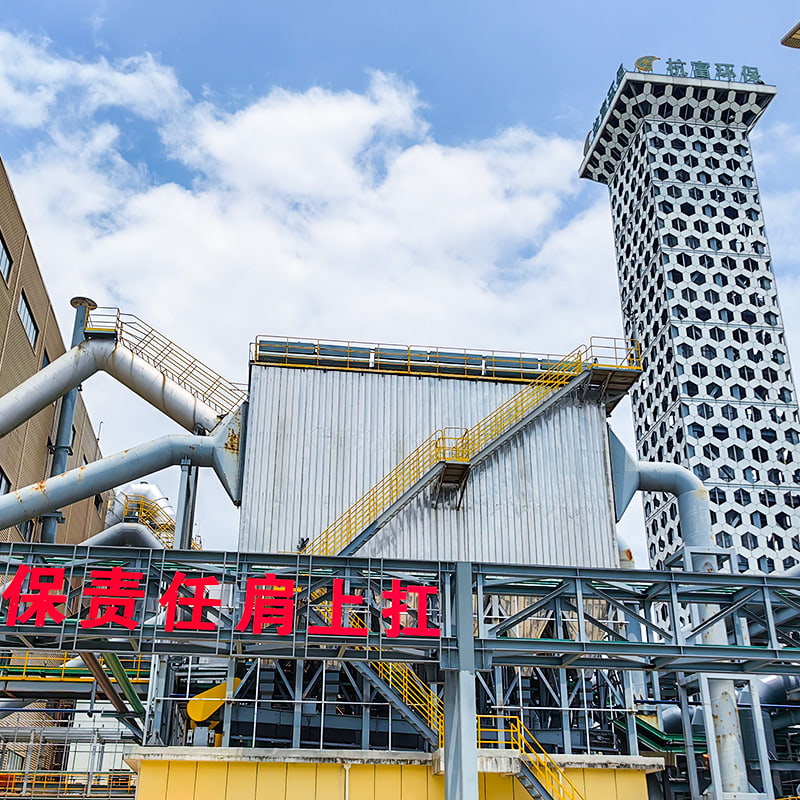

- Dust Collection Equipment

- Drying Equipment

- Conveying Equipment

- Elevating Equipment

- Crushing Equipment

- Screening Equipment

- Industrial Mixing and Agitation Equipment

- Granulation Equipment

- Calcination Equipment

- Cooling Equipment

- Bulk and Packaging Equipment

Dust Collection Equipment Supplier

Dust collection equipment is a key device used in industrial production and environmental management to capture, separate, and collect dust particles. It utilizes various technologies, including filtration, centrifugal separation, and electrostatic adsorption, to effectively treat pollutants such as smoke and dust generated during production. Based on their operating principles and application scenarios, common dust collection equipment can be categorized as bag filters, electrostatic precipitators, cyclone dust collectors, and wet dust collectors. Bag filters, with their efficient bag filtration capabilities, are widely used in industries with high dust concentrations, such as metallurgy, cement, and chemicals. Electrostatic precipitators utilize an electrostatic field to absorb dust and are suitable for treating flue gas in high-temperature and high-humidity environments. Cyclone dust collectors rely on centrifugal force to separate dust and are often used for primary purification of larger dust particles. Wet dust collectors capture dust with a water mist and are particularly effective in flammable and explosive environments.

The core purpose of dust collection equipment is to control dust pollution, protect the health of operators, and reduce wear and tear on production equipment, thereby extending its service life. From an environmental perspective, it can effectively reduce dust emissions, helping companies meet national and local environmental emission standards and avoid fines and production halts caused by excessive emissions. Furthermore, some dust collection equipment can recycle and reuse dust. For example, in industries like grain processing and mineral processing, collected dust can be re-entered into production processes, improving resource utilization. Whether in large industrial plants or small processing workshops, choosing the right dust collection equipment is crucial for achieving clean production and green development.

-

Factors Affecting the Efficiency of Compound Fertilizer Production Line The efficiency of the Compound Fertilizer Production Line is influenced by various factors, which can significantly impact production output, quality, and overall operational costs. Understanding these factors is crucial for man...

READ MORE -

The capacity of a compound fertilizer production line plays a crucial role in determining its operational efficiency, cost-effectiveness, and overall productivity. Understanding how to calculate and select the right capacity is essential for manufacturers looking to meet market demand while maintain...

READ MORE -

Establishing a compound fertilizer production line is a complex task that requires careful planning, proper site selection, and construction of the right facilities. This involves evaluating the physical space, technical infrastructure, environmental factors, and ensuring compliance with regulations...

READ MORE

Dust Collection Equipment is a crucial component in modern industrial operations, designed to capture, filter, and control airborne dust and particulate matter. Industrial processes such as chemical fertilizer production, cement manufacturing, metallurgy, woodworking, and food processing generate large volumes of dust, which can impact product quality, workplace safety, and environmental compliance. Dust collection equipment ensures that dust is effectively removed, collected, and safely discharged, supporting both operational efficiency and regulatory compliance.

Founded in 2007, Nantong Alisen Environmental Protection Technology Co., Ltd., based in Qutang Town Industrial Park, Haian City, Jiangsu Province, leverages extensive experience in machinery manufacturing to provide efficient and reliable dust collection solutions. With a focus on fertilizer and building materials machinery, the company’s dust collection equipment is integrated into complete production lines and standalone industrial applications.

1. Core Features of Dust Collection Equipment

Dust collection systems share several common features that define their performance and suitability for different applications:

-

High-Efficiency Filtration: Advanced filters capture fine and coarse dust particles, ensuring cleaner air and minimal material loss.

-

Stable Airflow: Systems maintain consistent suction to prevent dust accumulation and equipment clogging.

-

Adjustable Suction Power: Flexibility in airflow allows adaptation to various dust concentrations and particle sizes.

-

Reliable Dust Discharge: Automated or semi-automated mechanisms safely remove collected dust using rotary valves, screw conveyors, or hoppers.

-

Durability and Longevity: Equipment is designed for continuous industrial operations, reducing maintenance frequency and improving service life.

Typical products in this category include:

-

Baghouse Collectors: Use fabric filter bags to trap dust; suitable for high-volume, large-particle applications.

-

Cartridge Collectors: Employ pleated cartridge filters; ideal for fine dust and limited space.

-

Cyclone Separators: Utilize centrifugal force to separate heavy dust; low maintenance and suitable for continuous operations.

-

Mobile Dust Extractors: Flexible, portable solutions for localized dust control.

2. Comparing Different Dust Collection Systems

When selecting dust collection equipment, it is essential to consider the type of dust, operational requirements, and space constraints. Below is a comparison of common dust collector types:

| Feature | Baghouse Collector | Cartridge Collector | Cyclone Separator | Mobile Dust Extractor |

|---|---|---|---|---|

| Dust Particle Size | Large to medium | Fine | Medium to large | Medium |

| Filtration Efficiency | High | Very high | Medium | Variable |

| Space Requirement | Moderate | Low | Low | Very low |

| Maintenance Complexity | Medium | Low | Low | Low |

| Operational Cost | Moderate | Moderate | Low | Low |

| Best Application | Continuous industrial | Fine dust, limited space | Heavy dust, continuous | Localized or temporary |

This comparison helps industrial operators choose the most suitable dust collection system based on production scale, dust type, and operational priorities.

3. Applications in Industry

Dust Collection Equipment has a wide range of applications across different sectors:

-

Chemical Fertilizer Industry: Integrated into rotary kilns, drum granulators, crushers, dryers, and conveyors to control dust from raw materials and finished products.

-

Cement and Building Materials: Captures cement dust during production, minimizing emissions and equipment wear.

-

Metallurgy: Removes metal dust and fine particles generated during grinding, cutting, and material handling.

-

Woodworking and Food Processing: Reduces airborne dust, ensuring product quality and worker safety.

In fertilizer production, for example, Nantong Alisen’s dust collection systems are deployed across compound fertilizer, organic fertilizer, and bulk blending fertilizer lines. These systems ensure compliance with environmental standards while maintaining production efficiency.

4. Operation Principles

Dust collection equipment operates based on several physical principles:

-

Filtration: Dust-laden air passes through filter media, where particles are trapped and cleaned air is released.

-

Centrifugal Separation: In cyclone separators, the air rotates at high speed; centrifugal force pushes dust to the outer wall, allowing clean air to exit.

-

Electrostatic Precipitation: In specialized systems, charged particles are attracted to collection plates, removing fine dust from the airflow.

-

Airflow Control: Proper system design ensures uniform air velocity, preventing filter clogging and maintaining efficiency.

These principles allow systems to handle varying dust loads, particle sizes, and operational conditions.

5. Maintenance and Best Practices

Maintaining dust collection equipment is critical to performance and longevity:

-

Filter Inspection and Replacement: Regularly inspect filters; replacement typically occurs every 6–12 months depending on dust type.

-

Cleaning Mechanisms: Systems may include pulse-jet cleaning, shaker systems, or reverse air to remove accumulated dust from filters.

-

System Monitoring: Pressure gauges, flow meters, and alarms can indicate when maintenance is required.

-

Dust Disposal: Ensure collected dust is safely removed and handled to prevent environmental contamination.

Proper maintenance reduces downtime, prevents efficiency loss, and ensures compliance with environmental regulations.

6. Frequently Asked Questions (FAQ)

-

How do I choose the right dust collector? Consider dust type, particle size, airflow requirements, space, and operational frequency. Consulting manufacturers like Nantong Alisen helps ensure proper selection.

-

Can dust collectors integrate with existing equipment? Yes, modern systems can connect to rotary kilns, drum granulators, crushers, conveyors, and other machinery.

-

What are the energy requirements? Power consumption varies by system type and airflow; energy-efficient models minimize electricity usage while maintaining performance.

-

How is collected dust discharged? Dust is typically conveyed to hoppers or collection bins using rotary valves or screw conveyors. Automation improves safety and reduces labor.

7. Advantages of Professional Dust Collection Equipment

Using properly designed dust collection equipment provides multiple benefits:

-

Reduces airborne dust, improving workplace safety and hygiene.

-

Minimizes environmental emissions, supporting regulatory compliance.

-

Extends equipment lifespan by preventing dust accumulation.

-

Enhances product quality by reducing contamination.

-

Lowers maintenance and operational costs through efficient system design.

Nantong Alisen Environmental Protection Technology Co., Ltd. combines industrial experience with engineering expertise to deliver dust collection solutions that meet diverse industrial needs. Their equipment supports both large-scale production lines and smaller, localized applications, ensuring consistent performance and operational reliability.

En

En

English

English  Français

Français  русский

русский  中文简体

中文简体  عربى

عربى  Español

Español